When you embark on an exciting project – whether it’s building a precise and error free desktop CNC machine or a smoothly moving robotic arm – choosing the right core power components is often the key to success. Among numerous execution components, micro stepper motors have become the preferred choice for makers, engineers, and manufacturers due to their precise open-loop control, excellent torque retention, and relatively low cost.

However, faced with a wide variety of models and complex parameters, how to choose the most suitable micro stepper motor for your robot or CNC machine? Choosing the wrong option may result in substandard accuracy, insufficient power, or even project failure. This guide will serve as your ultimate selection manual, taking you step by step to clarify all key factors and make wise decisions.

Step 1: Understand the core requirements – the fundamental difference between robots and CNC

Before examining any parameters, you must clarify the core requirements of your application scenario for the motor.

Robot projects (such as robotic arms, mobile robots):

Core requirements: dynamic response, weight, size, and efficiency. The joints of robots require frequent start stop, variable speed, and direction changes, and the weight of the motor directly affects the overall load and power consumption.

Key indicators: Pay more attention to the torque speed curve (especially medium to high speed torque) and power to weight ratio.

CNC machine tools (such as 3-axis engraving machines, laser cutting machines):

Core requirements: thrust, smoothness, maintaining torque, and precision. CNC machine tools need to overcome huge resistance during cutting or engraving, maintain smooth motion to avoid vibration, and accurately position.

Key indicators: Pay more attention to maintaining torque at low speeds, micro step resolution to reduce vibration, and motor rigidity.

Understanding this fundamental difference is the foundation for all subsequent selection decisions.

Step 2: Interpretation of the Five Key Parameters of Micro stepper Motors

Here are five core parameters that you must pay attention to in the data manual.

1. Size and torque – the cornerstone of strength

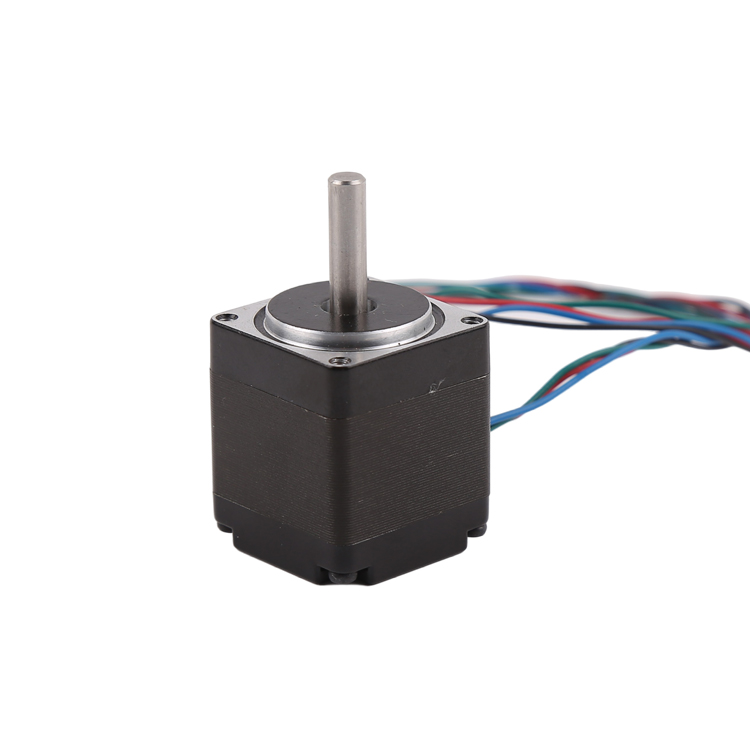

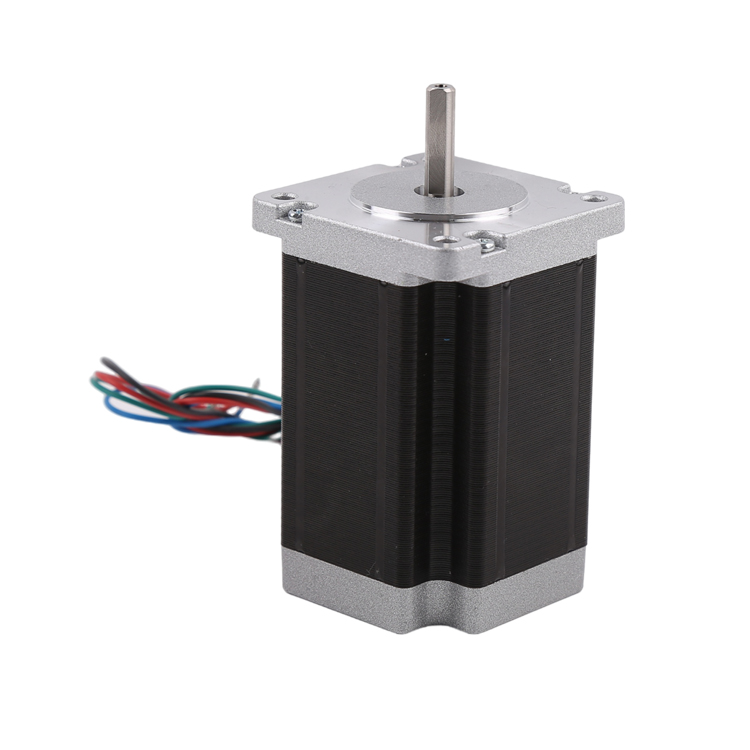

Size (machine base number): usually expressed in millimeters (such as NEMA 11, 17, 23). The NEMA standard defines the installation dimensions of motors, not their performance. NEMA 17 is the most popular size for desktop robots and CNC, achieving a good balance between size and torque. The smaller NEMA 11/14 is suitable for light load robot joints; The larger NEMA 23 is suitable for large CNC machine tools.

Maintain torque: Unit is N · cm or Oz · in. This is the maximum torque that the motor can generate when powered but not rotating. This is the most critical indicator for measuring the strength of a motor. For CNC machine tools, you need sufficient holding torque to resist cutting forces; For robots, it is necessary to calculate the maximum torque required for the joints.

How to estimate the required torque?

For CNC machine tools, a rough rule of thumb is that a torque that can provide at least 20-30N (approximately 2-3 kilograms) axial thrust is required. This needs to be converted through the lead and efficiency of the screw. For robots, complex dynamic calculations are required based on arm length, load weight, and acceleration. Be sure to leave a torque margin of 30% -50% to cope with uncertain factors such as friction and inertia.

2.Step angle and accuracy – the soul of step

Step angle: such as 1.8 ° or 0.9 °. A 1.8 ° motor rotates once every 200 steps, while a 0.9 ° motor requires 400 steps. The smaller the step angle, the higher the inherent accuracy of the motor. A 0.9 ° motor is usually smoother when running at low speeds.

3. Current and Voltage – Matching of Drivers

Phase current: Unit is Ampere (A). This is the maximum rated current that each phase winding of the motor can withstand. This parameter directly determines which drive you should choose. The output current capability of the driver must be matched with the motor.

Voltage: Motors are typically rated for their rated voltage, but the actual operating voltage can be much higher than this (determined by the driver). Higher voltage helps improve the high-speed performance of the motor.

4. Inductance and high-speed performance – key factors that are easily overlooked

Inductance is a key factor affecting the high-speed torque of a motor. Low inductance motors can establish current faster, resulting in better performance at high speeds. If the joints of your robot need to rotate quickly, or if your CNC machine wants to increase the feed rate, you should prioritize choosing models with low inductance.

5. Shaft type and outgoing line method – details of mechanical connection

Shaft types: optical axis, single flat shaft, double flat shaft, gear shaft. D-type trimming (single flat shaft) is the most common and can effectively prevent the coupling from slipping.

Outgoing method: direct outgoing or plug-in. The plug-in method (such as 4-pin or 6-pin aviation head) is convenient for installation and maintenance, and is a more professional choice.

Step 3: An indispensable partner – how to choose a stepper motor driver

The motor itself cannot work and must be paired with a stepper motor driver. The quality of the driver directly determines the final performance of the system.

Microstep: Subdivide a whole step into multiple microsteps (such as 16, 32, 256 microsteps). The main function of micro stepping is to make the motor motion extremely smooth, greatly reducing vibration and noise, which is crucial for the surface quality of CNC machine tools.

Current control: Excellent drivers have automatic half current function. Automatically reduce current when the motor is stationary, reducing heat generation and energy consumption.

Common driver chips/modules:

Entry level: A4988- Low cost, suitable for simple robot projects.

Mainstream Choice: TMC2208/TMC2209- Supports silent driving (StealthShop mode), runs extremely quietly, is an excellent choice for CNC machine tools, and provides more advanced control functions.

High performance: DRV8825/TB6600- provides higher current and voltage support, suitable for applications that require greater torque.

Remember: a good driver can maximize the potential of the motor.

Step 4: Practical Selection Process and Common Misconceptions

Four step selection method:

Define load: Clearly define the maximum weight, required acceleration, and speed that your machine needs to move.

Calculate torque: Use an online torque calculator or mechanical formula to estimate the required torque.

Preliminary selection of motors: Select 2-3 candidate models based on torque and size requirements, and compare their torque speed curves.

Match driver: Select the appropriate driver module and power supply based on the phase current of the motor and the required functions (such as mute, high subdivision).

Common Misconceptions (Avoiding Pits Guide):

Misconception 1: The greater the torque, the better. Excessive torque means larger motors, heavier weight, and higher power consumption, which is particularly detrimental to robot joints.

Misconception 2: Only focus on maintaining torque and ignore high-speed torque. The motor has a high torque at low speeds, but as the speed increases, the torque will decrease. Be sure to check the torque speed curve chart.

Misconception 3: Insufficient power supply. Power supply is the energy source of the system. A weak power supply cannot drive the motor to perform at its full potential. The power supply voltage should be at least the midpoint of the rated voltage of the driver, and the current capacity should be greater than 60% of the sum of all motor phase currents.

Step 5: Advanced Considerations – When Do We Need to Consider Closed Loop Systems?

Traditional stepper motors are open-loop controlled, and if the load is too large and causes the motor to “lose step”, the controller cannot be aware of it. This is a fatal flaw for applications that require 100% reliability, such as commercial grade CNC machining.

The closed-loop stepper motor integrates an encoder at the rear end of the motor, which can monitor the position in real time and correct errors. It combines the advantages of high torque for stepper motors and reliability for servo motors. If your project:

No risk of deviation is allowed.

It is necessary to fully utilize the maximum performance of the motor (closed-loop can provide higher speeds).

It is used for commercial products.

So, investing in a closed-loop stepper system is worth it.

Conclusion

Choosing the appropriate micro stepper motor for your robot or CNC machine is a system engineering that requires comprehensive consideration of mechanical, electrical, and control aspects. There is no ‘best’ motor, only the ‘most suitable’ motor.

To summarize the core points, starting from the application scenario, robots prioritize dynamic performance and weight, while CNC machine tools prioritize static torque and stability. Grasp firmly on the key parameters of torque, current, and inductance, and equip it with an excellent driver and sufficient power supply. Through the guidance in this article, I hope you can confidently make the perfect choice for your next great project, ensuring that your creations run accurately, powerfully, and reliably.

Post time: Sep-25-2025