Deep comparison between micro stepper motor and N20 DC motor: when to choose torque and when to choose cost?

In the design process of precision equipment, the choice of power source often determines the success or failure of the entire project. When the design space is limited and a choice needs to be made between micro stepper motors and ubiquitous N20 DC motors, many engineers and procurement managers will be deeply thinking: should they pursue precise control and high torque of stepper motors, or choose the cost advantage and simple control of DC motors? This is not only a technical multiple-choice question, but also an economic decision related to the project’s business model.

I、 Quick Overview of Core Features: Two Different Technical Pathways

Micro stepper motor: the precision king of open-loop control

Working principle: Through digital pulse control, each pulse corresponds to a fixed angular displacement

Core advantages: precise positioning, high holding torque, excellent low-speed stability

Typical applications: 3D printers, precision instruments, robot joints, medical equipment

N20 DC Motor: Cost First Efficiency Solution

Working principle: Control speed and torque through voltage and current

Core advantages: low cost, simple control, wide speed range, high energy efficiency

Typical applications: small pumps, door lock systems, toy models, ventilation fans

II、 Deep Comparison of Eight Dimensions: Data Reveals the Truth

1. Positioning accuracy: the difference between millimeter level and step level

Micro stepper motor: with a typical step angle of 1.8 °, it can achieve up to 51200 subdivision/rotation through micro stepper drive, and the positioning accuracy can reach ± 0.09 °

N20 DC motor: no built-in positioning function, requires encoder to achieve position control, incremental encoder usually provides 12-48CPR

Engineer insight: In scenarios that require absolute position control, stepper motors are a natural choice; For applications that require higher speed control, DC motors may be more suitable.

2. Torque characteristics: Maintain the game between torque and speed torque curve

Micro stepper motor: with excellent holding torque (such as NEMA 8 motor up to 0.15N · m), stable torque at low speeds

N20 DC motor: torque decreases with increasing speed, high no-load speed but limited locked rotor torque

Comparison Table of Actual Test Data:

| Performance parameters | Micro stepper motor (NEMA 8) | N20 DC motor (6V) |

| Maintain a torque | 0.15N · m | |

| Locking torque | 0.015N · m | |

| rated speed | Depends on the pulse frequency | 10000RPM |

| maximum efficiency | 70% | 85% |

3. Control complexity: technical differences between pulse vs. PWM

Stepper motor control: requires a dedicated stepper driver to provide pulse and direction signals

DC motor control: Simple H-bridge circuit can achieve forward and reverse rotation and speed regulation

4. Cost Analysis: Reflections from Unit Price to Total System Cost

Unit price of motor: N20 DC motor usually has a significant price advantage (bulk purchase about 1-3 US dollars)

Total system cost: The stepper motor system requires additional drivers, but the DC motor positioning system requires encoders and more complex controllers

Procurement perspective: Small batch R&D projects may focus more on unit price, while mass production projects must calculate the total system cost.

III、 Decision Guide: Precise Selection of Five Application Scenarios

Scenario 1: Applications that require precise position control

Recommended choice: Micro stepper motor

Reason: Open loop control can achieve precise positioning without the need for complex feedback systems

Example: 3D printer extrusion head movement, precise positioning of microscope platform

Scenario 2: Mass production that is extremely cost sensitive

Recommended choice: N20 DC motor

Reason: Significantly reduce BOM costs while ensuring basic functionality

Example: Home appliance valve control, low-cost toy drive

Scenario 3: Light load applications with extremely limited space

Recommended choice: N20 DC motor (with gearbox)

Reason: Small size, providing reasonable torque output in limited space

Example: drone gimbal adjustment, small robot finger joints

Scenario 4: Vertical applications requiring high holding torque

Recommended choice: Micro stepper motor

Reason: Can still maintain position after power outage, no mechanical braking device required

Example: Small lifting mechanism, camera pitch angle maintenance

Scenario 5: Applications requiring a wide speed range

Recommended choice: N20 DC motor

Reason: PWM can smoothly achieve large-scale speed regulation

Example: Flow regulation of micro pumps, wind speed control of ventilation equipment

IV、 Hybrid solution: breaking the binary mindset

In some high-performance applications, a combination of two technologies can be considered:

The main motion uses a stepper motor to ensure accuracy

Auxiliary functions use DC motors to control costs

Closed loop stepping provides a compromise solution in situations where reliability is required

Innovation case: In the design of a high-end coffee machine, a stepper motor is used to ensure precise stopping position for the brewing head lifting, while a DC motor is used to control costs for the water pump and grinder.

V、 Future Trends: How Technological Developments Affect Choices

Evolution of stepper motor technology:

Simplified system design of intelligent stepper motor with integrated driver

New magnetic circuit design with higher torque density

Prices have been decreasing year by year, penetrating towards mid-range applications

Improvement of DC motor technology:

Brushless DC motor (BLDC) provides longer service life

Intelligent DC motors with integrated encoders are beginning to emerge

The application of new materials continues to reduce costs

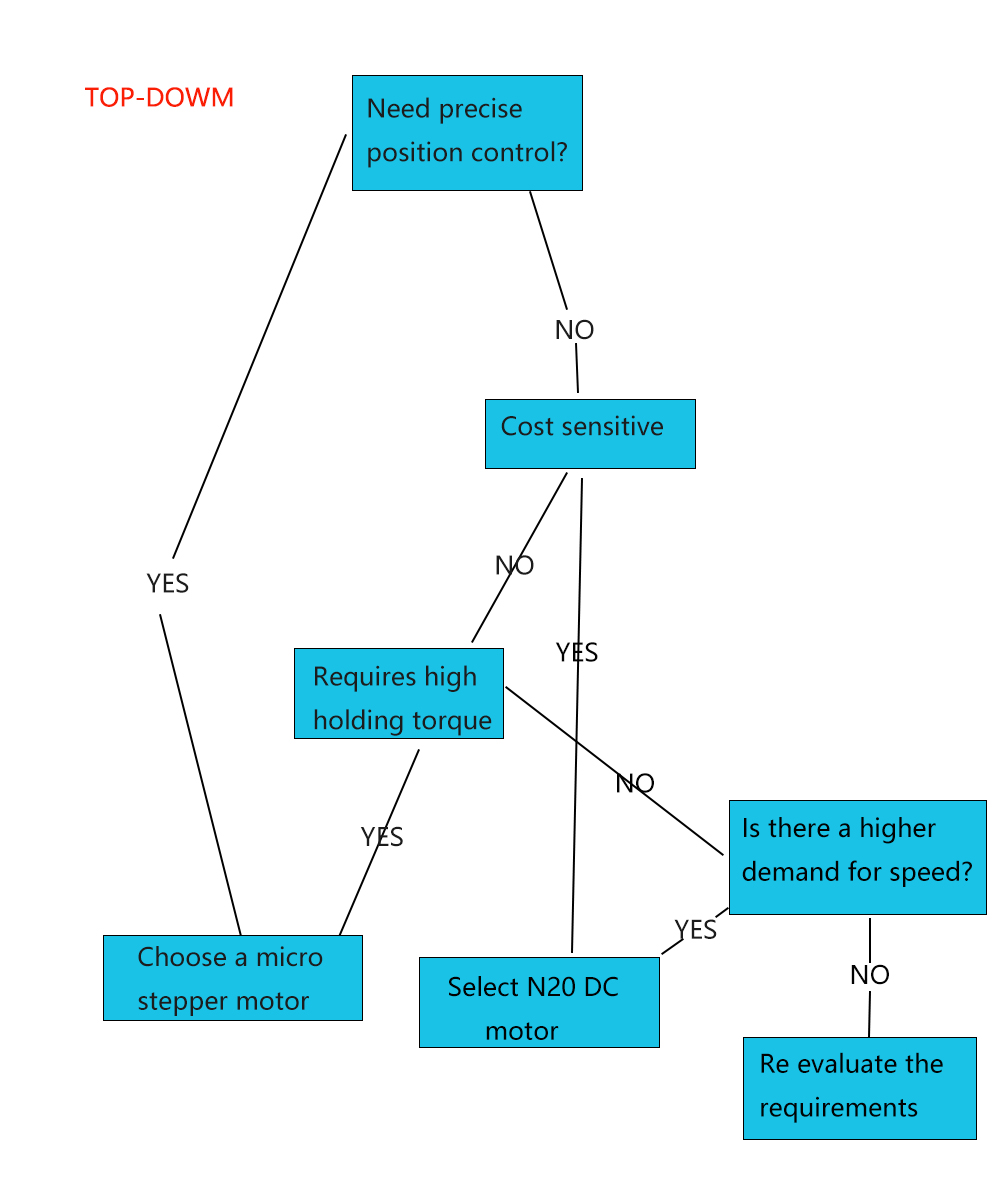

VI、 Practical selection process diagram

By following the following decision-making process, choices can be made systematically:

Conclusion: Finding a Balance between Technological Ideals and Business Reality

Choosing between a micro stepper motor or an N20 DC motor is never a simple technical decision. It embodies the art of balancing engineers’ pursuit of performance with procurement’s control of costs.

Core decision-making principles:

When accuracy and reliability are the primary considerations, choose a stepper motor

When cost and simplicity dominate, choose a DC motor

When in the middle zone, carefully calculate the total system cost and long-term maintenance cost

In today’s rapidly iterating technological environment, wise engineers do not stick to a single technical route, but make the most rational choices based on the specific constraints and business goals of the project. Remember, there is no “best” motor, only the “most suitable” solution.

Post time: Oct-13-2025