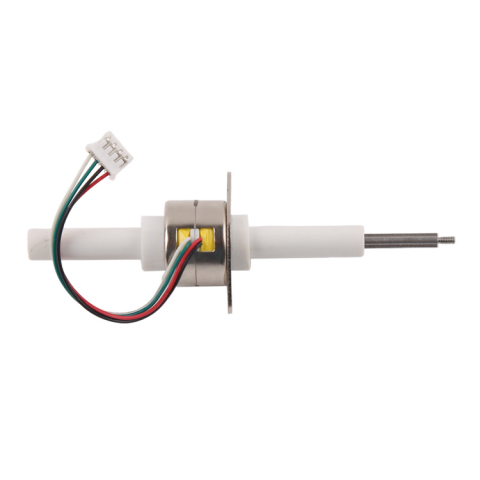

In today’s rapidly developing medical technology, miniaturization, precision, and intelligence have become the core directions of device evolution. Among numerous precision motion control components, micro linear stepper motors equipped with 7.5/15 degree dual step angles and M3 screws (especially the 20mm stroke model) are quietly becoming indispensable “muscles and nerves” in modern medical equipment. This sophisticated power source, with its outstanding performance and compact body, injects unprecedented precision and reliability into diagnostic, therapeutic, and life support equipment.

Medical Micro Devices: The Ultimate Challenge for Motion Control

The requirements for driving components in the medical environment are almost stringent, especially in portable, implantable, and highly integrated devices:

Submillimeter or even micrometer level accuracy: precise drug delivery, cell manipulation, laser positioning and other operations cannot tolerate any deviation

Ultimate space utilization: Every inch of land is valuable inside the device, and the driving components must be extremely compact and lightweight.

Ultra quiet operation: reduces patient anxiety and avoids interfering with sensitive medical environments such as operating rooms and monitoring rooms.

Ultra high reliability: Equipment failures may be life-threatening, requiring long component life and extremely low failure rates.

Low power consumption and heat generation are crucial for battery powered devices and applications close to the human body.

Easy to integrate and control: supports open-loop or simple closed-loop, simplifying system design.

Strict biocompatibility and cleanliness: meet medical regulatory requirements (such as ISO 13485, FDA QSR).

7.5/15 degree+M3 screw micro motor: a powerful tool to solve the problem of medical precision control

M3 screw drive: a small yet highly capable precision engine

The core of miniaturization: M3 screw (nominal diameter 3mm) is currently the widely used standard for micro precision screws. Its small diameter is the key to achieving the ultimate compactness of the driving unit

Direct and efficient, with guaranteed accuracy: The rotational motion of the motor is directly converted into high-precision linear displacement, with a simple and reliable structure. Small pitch (usually 0.5mm or 0.35mm) is the physical basis for its high resolution. Combining the characteristics of stepper motors, it is easy to achieve micrometer level (μ m) positioning accuracy and excellent repeatability.

Power off self-locking and safety protection: The inherent self-locking characteristic of the screw can reliably maintain the load position when the motor is powered off, preventing accidental movement caused by gravity or external forces, which is crucial in medical applications.

High rigidity, as stable as a rock: Although small, a well-designed M3 screw transmission system can provide sufficient rigidity and thrust to meet the load requirements of most micro medical devices, ensuring stable and reliable operation.

Miniature Design: Conquering Space Limitations

Ultra small size, worry free integration: Using a combination of M3 screws and compact stepper motors, the entire linear module is compact and lightweight, making it easy to embed into devices with extremely limited space, such as handheld instruments, endoscope accessories, portable diagnostic devices, wearable devices, etc.

Lightweight and low inertia: significantly reduces the weight of moving parts, bringing faster acceleration/deceleration response, lower power consumption, and smaller operating noise, improving overall system performance and energy efficiency.

The shining application of micro precision power in the medical fiel

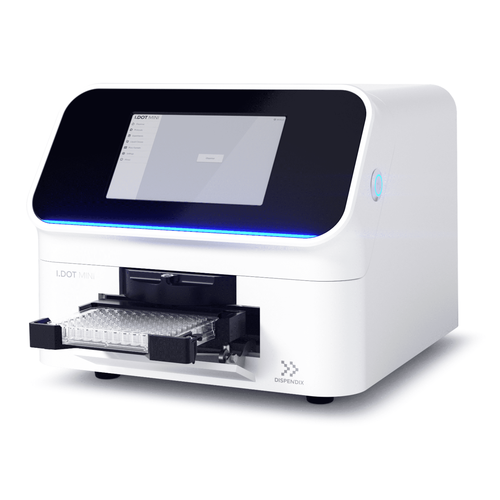

In vitro diagnostic (IVD) equipment: the cornerstone of precise analysis

Micro upgraded pipetting and dispensing: Drive precision injection pumps or micro pistons to achieve ultra-high precision suction, distribution, and mixing of reagents and samples ranging from nanoliters (nL) to microliters (μ L). Fine control in 7.5 degree mode is the core to ensure the accuracy of detection results.

Micro valve control: Accurately control the opening and closing degree and timing of micro solenoid valves or needle valves in the fluid pathway, and manage the reagent flow path. The precise displacement and fast response of M3 screw are key.

Precision positioning of microplates/glass slides: Achieve sub micron level precise positioning of sample carriers in microscope automatic platforms or high-throughput analyzers, ensuring accurate imaging or detection points. The dual step angle flexibly meets the needs of fast scanning and precise positioning.

Colorimetric cup/flow cell adjustment: Fine tune the position of key components in the optical detection path, optimize the optical path, and improve detection sensitivity and signal-to-noise ratio.

Drug infusion and treatment equipment: precise infusion of life

Insulin pump/microinjection pump: drives micro pump pistons or precision rollers to achieve extremely precise basal rate and high-dose insulin infusion before meals. The combination of 7.5 degree mode and M3 screw is a reliable guarantee for achieving precise drug delivery at the microliter level and ensuring patient safety.

Pain pump (PCA): Provides precise doses of pain medication as needed to respond to patient needs. Reliability and accuracy are indispensable.

Inhalation drug delivery device: Accurately control the release dose and speed of dry powder or nebulized drugs.

Targeted drug delivery system (research frontier): In micro implantable or interventional devices, driving micro mechanisms to achieve precise local drug release.

Endoscope and minimally invasive surgical instruments: can see clearly and move accurately

Endoscope lens focusing/focusing mechanism: Within the small operating part of the endoscope, the lens group is driven to make small displacements, achieving fast and accurate autofocus and improving the clarity of the surgical field of view.

Microsurgical instrument drive: In robot assisted minimally invasive surgery (RAS), small movements such as opening and closing of forceps, tool extension and contraction, or joint bending are driven from the end of hand instruments or fine handheld instruments, providing precise surgical force feedback

Endoscope accessory control: Accurately control the extension length and force of biopsy forceps, snare and other accessories.

Respiratory therapy and life support: stable and reliable airflow protection

Portable/home ventilator valve control: Accurately adjust the oxygen and air mixing ratio, flow rate, and positive end expiratory pressure (PEEP) valve to meet the personalized needs of patients. Silent operation and reliability are crucial.

Anesthesia machine gas flow control: precise management of anesthesia gas delivery.

Micro air pump driver: provides stable airflow in portable respiratory assistance devices or monitoring devices.

Imaging diagnostic equipment: the behind the scenes hero of clear imaging

Localization of miniaturized medical imaging probes: such as fine-tuning of micro arrays inside portable ultrasound probes or driving of automatic scanning mechanisms.

Optical coherence tomography (OCT): Control the precise displacement of the reference arm optical path for depth scanning.

Microscope automatic platform: Drive the stage or objective lens for fine Z-axis focusing or XY axis micro motion.

Rehabilitation and Assistive Equipment: Care in the Details

Precision adjustable prostheses/orthotics: achieve micro and adaptive adjustment of joint angles or support forces.

Intelligent drug delivery patch: driving a micro pump to achieve precise and controllable release of transdermal drugs.

High precision rehabilitation training equipment: providing small, controllable resistance or assistance.

Summary of Core Advantages: Why does healthcare choose it?

Unparalleled accuracy and resolution: 7.5 degree mode+M3 fine pitch, achieving micrometer level positioning capability, meeting the most demanding medical precision control needs.

Excellent space efficiency: ultimate miniaturization design, conquering the space challenges of portable, implantable, and highly integrated devices.

Ultra quiet operation: Optimized design brings low vibration and noise, enhancing patient comfort and medical environment experience.

High reliability and long lifespan: The structure is simple and sturdy, with no electric brush wear, meeting the long-term stable operation and low maintenance requirements of medical equipment.

Power off position maintenance: The self-locking feature of the screw provides power off safety protection to prevent accidental movement.

Easy to control and integrate: open-loop control is simple and reliable, compatible with mainstream drivers, and accelerates device development cycles.

Compliance with medical certification foundation: Mature component design and manufacturing processes help meet medical quality management system requirements such as ISO 13485.

conclusion

In the future vision of pursuing more precision, minimally invasive, intelligent, and convenient medical technology, the micro linear stepper motor with a 7.5/15 degree step angle and M3 screw, especially the 20mm stroke model, has become a key engine driving innovation with the precision power contained in its miniature embodiment. From precise testing in the laboratory to meticulous operation in the operating room, from continuous treatment of patients to daily health management, it silently plays an irreplaceable role. Choosing this advanced micro power solution means endowing medical equipment with more precise control, more compact design, quieter operation, and more reliable performance, ultimately contributing solid strength to improving diagnosis and treatment effectiveness, enhancing patient experience, and promoting medical progress. Explore this miniature precision power source and inject core competitiveness into your next-generation medical equipment!

Post time: Jul-18-2025