Before exploring micro stepper motors, let’s start with the basics. A stepper motor is an electromechanical device that converts electrical pulses into precise mechanical movements. Unlike traditional DC motors, stepper motors move in discrete “steps,” allowing for exceptional control over position, speed, and torque. This makes them ideal for applications like 3D printers, CNC machines, and automated systems where precision is non-negotiable.

Defining a Micro Stepper Motor

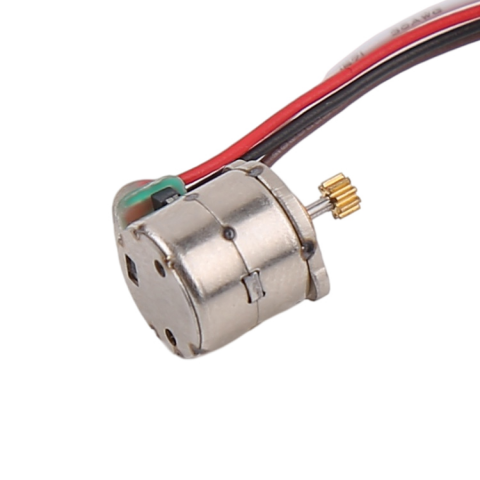

A micro stepper motor is a miniaturized version of a standard stepper motor, designed to deliver the same precision in a significantly smaller package. These motors typically measure less than 20mm in diameter and weigh just a few grams, making them perfect for space-constrained applications. Despite their size, they retain the core features of traditional steppers, including:

Step-wise motion control (e.g., 1.8° or 0.9° per step).

High torque-to-size ratio for compact systems.

Open-loop control (no feedback sensors required).

Micro stepper motors often incorporate advanced microstepping technology, which divides each physical step into smaller increments for smoother motion and higher resolution.

How Does a Micro Stepper Motor Work?

Micro stepper motors operate on the same principles as standard steppers but with refined engineering for miniaturization. Here’s a simplified breakdown:

Electromagnetic Coils: The motor contains multiple coils arranged in phases.

Pulse Signals: A driver sends electrical pulses to energize the coils in sequence.

Magnetic Rotation: The interaction between the stator’s magnetic field and the rotor’s permanent magnets creates rotational movement.

Microstepping: By modulating current between coils, the motor achieves fractional steps, enabling ultra-precise positioning.

For example, a motor with a 1.8° step angle can achieve 0.007° resolution using 256 microsteps—critical for tasks like lens focusing in cameras or syringe pumping in medical devices.

Key Advantages of Micro Stepper Motors

Why choose a micro stepper motor over other motor types? Here are their standout benefits:

Precision and Accuracy

Microstepping technology minimizes vibration and enables sub-degree positioning, making these motors ideal for lab equipment, optical systems, and micro-robotics.

Compact and Lightweight Design

Their small footprint allows integration into portable devices, wearable tech, and drones without sacrificing performance.

Energy Efficiency

Low power consumption and minimal heat generation extend battery life in wireless applications.

Cost-Effective Control

Open-loop systems eliminate the need for expensive encoders or feedback sensors.

High Torque at Low Speeds

Micro steppers deliver consistent torque even in slow-speed operations, such as valve control or conveyor systems.

Applications of Micro Stepper Motors

From healthcare to automation, micro stepper motors power innovations across industries:

Medical Devices: Used in insulin pumps, ventilators, and surgical robots for precise fluid dispensing and movement.

Consumer Electronics: Enable autofocus in smartphone cameras, vibration control in gaming controllers, and disc drives.

Industrial Automation: Drive miniature conveyor belts, sorting systems, and CNC tool adjustments.

Robotics: Power joints and grippers in micro-robots for delicate tasks like circuit board assembly.

Aerospace: Control satellite antenna positioning and drone gimbal stabilization.

Choosing the Right Micro Stepper Motor

When selecting a micro stepper motor, consider these factors:

Step Angle: Smaller angles (e.g., 0.9°) offer higher resolution.

Torque Requirements: Match torque to load demands.

Voltage and Current Ratings: Ensure compatibility with your power supply.

Environmental Conditions: Opt for waterproof or dustproof models for harsh environments.

Future Trends in Micro Stepper Motor Technology

As industries demand smarter, smaller, and more efficient systems, micro stepper motors are evolving with:

Integrated Drivers: Combining motors with onboard drivers for plug-and-play usability.

IoT Connectivity: Enabling remote control and diagnostics in smart factories.

Material Innovations: Lighter, stronger materials like carbon fiber composites.

Conclusion

A micro stepper motor is a powerhouse of precision engineering, offering unmatched control in miniature form. Whether you’re designing a cutting-edge medical device or optimizing a consumer gadget, understanding this technology can unlock new possibilities for innovation. By leveraging their compact size, energy efficiency, and microstepping capabilities, industries can push the boundaries of automation and accuracy.

Post time: May-23-2025