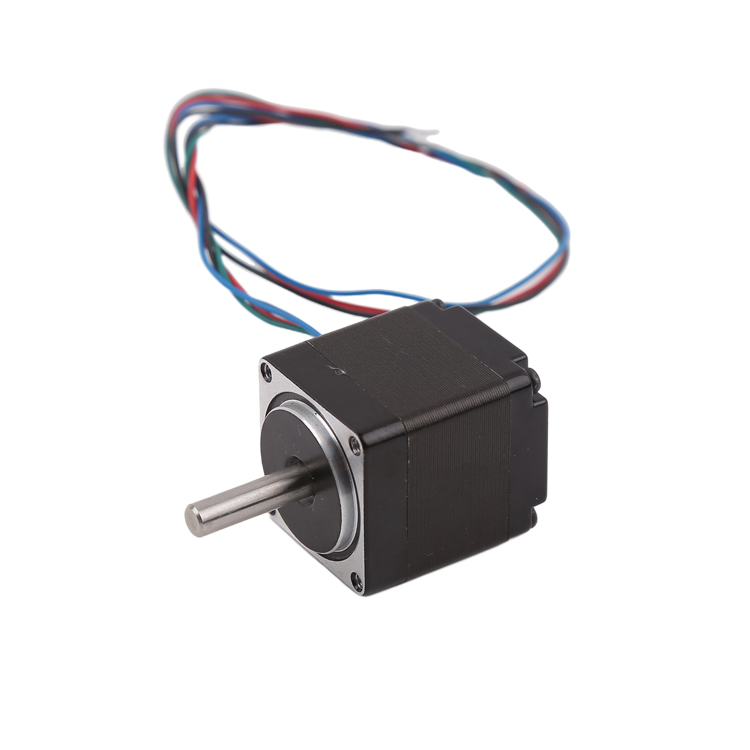

Hot potato! “- This may be the first touch that many engineers, makers, and students have on micro stepper motors during project debugging. It is an extremely common phenomenon for micro stepper motors to generate heat during operation. But the key is, how hot is normal? And how hot does it indicate a problem?

Severe heating not only reduces motor efficiency, torque, and accuracy, but also accelerates internal insulation aging in the long run, ultimately leading to permanent damage to the motor. If you are struggling with the heat of micro stepper motors on your 3D printer, CNC machine, or robot, then this article is for you. We will delve into the root causes of fever and provide you with 5 immediate cooling solutions.

Part 1: Root cause exploration – why does a micro stepper motor generate heat?

Firstly, it is necessary to clarify a core concept: the heating of micro stepper motors is inevitable and cannot be completely avoided. Its heat mainly comes from two aspects:

1. Iron loss (core loss): The stator of the motor is made of stacked silicon steel sheets, and the alternating magnetic field will generate eddy currents and hysteresis in it, causing heat generation. This part of the loss is related to the motor speed (frequency), and the higher the speed, the greater the iron loss is usually.

2. Copper loss (winding resistance loss): This is the main source of heat and also a part that we can focus on optimizing. It follows Joule’s law: P=I ² × R.

P (power loss): The power directly converted into heat.

I (current): The current flowing through the motor winding.

R (Resistance): The internal resistance of the motor winding.

Simply put, the amount of heat generated is proportional to the square of the current. This means that even a small increase in current can lead to a square fold surge in heat. Almost all of our solutions revolve around how to scientifically manage this current (I).

Part 2: Five major culprits – Analysis of specific causes leading to severe fever

When the motor temperature is too high (such as being too hot to touch, usually exceeding 70-80 ° C), it is usually caused by one or more of the following reasons:

The first culprit is that the driving current is set too high

This is the most common and primary checkpoint. In order to obtain greater output torque, users often turn the current regulating potentiometer on drivers (such as A4988, TMC2208, TB6600) too much. This directly resulted in the winding current (I) far exceeding the rated value of the motor, and according to P=I ² × R, the heat increased sharply. Remember: the increase in torque comes at the cost of heat.

Second culprit: Improper voltage and driving mode

Supply voltage too high: The stepper motor system adopts a “constant current drive”, but a higher supply voltage means that the driver can “push” the current into the motor winding at a faster speed, which is beneficial for improving high-speed performance. However, at low speeds or at rest, excessive voltage can cause the current to chop too frequently, increasing switch losses and causing both the driver and motor to heat up.

Not using micro stepping or insufficient subdivision: In full step mode, the current waveform is a square wave, and the current changes dramatically. The current value in the coil suddenly changes between 0 and the maximum value, resulting in large torque ripple and noise, and relatively low efficiency. And micro stepping smooths the current change curve (approximately a sine wave), reduces harmonic losses and torque ripple, runs more smoothly, and usually reduces average heat generation to a certain extent.

Third culprit: Overloading or mechanical problems

Exceeding rated load: If the motor operates under a load close to or exceeding its holding torque for a long time, in order to overcome resistance, the driver will continue to provide high current, resulting in sustained high temperature.

Mechanical friction, misalignment, and jamming: Improper installation of couplings, poor guide rails, and foreign objects in the lead screw can all cause additional and unnecessary loads on the motor, forcing it to work harder and generate more heat.

Fourth culprit: Improper motor selection

A small horse pulling a big cart. If the project itself requires a large torque, and you choose a motor that is too small in size (such as using NEMA 17 to do NEMA 23 work), then it can only operate under overload for a long time, and severe heating is an inevitable result.

Fifth culprit: Poor working environment and poor heat dissipation conditions

High ambient temperature: The motor operates in a closed space or in an environment with other heat sources nearby (such as 3D printer beds or laser heads), which greatly reduces its heat dissipation efficiency.

Insufficient natural convection: The motor itself is a heat source. If the surrounding air does not circulate, the heat cannot be carried away in a timely manner, leading to heat accumulation and continuous temperature rise.

Part 3: Practical Solutions -5 Effective Cooling Methods for Your Micro Stepper Motor

After identifying the cause, we can prescribe the right medicine. Please troubleshoot and optimize in the following order:

Solution 1: Accurately set the driving current (most effective, first step)

Operation method: Use a multimeter to measure the current reference voltage (Vref) on the driver, and calculate the corresponding current value according to the formula (different formulas for different drivers). Set it to 70% -90% of the rated phase current of the motor. For example, a motor with a rated current of 1.5A can be set between 1.0A and 1.3A.

Why is it effective: It directly reduces I in the heat generation formula and reduces heat loss by square times. When the torque is sufficient, this is the most cost-effective cooling method.

Solution 2: Optimize the driving voltage and enable micro stepping

Drive voltage: Choose a voltage that matches your speed requirements. For most desktop applications, 24V-36V is a range that strikes a good balance between performance and heat generation. Avoid using excessively high voltage

Enable high subdivision micro stepping: Set the driver to a higher micro stepping mode (such as 16 or 32 subdivision). This not only brings smoother and quieter movement, but also reduces harmonic losses due to the smooth current waveform, which helps to reduce heat generation during medium and low-speed operation.

Solution 3: Installing heat sinks and forced air cooling (physical heat dissipation)

Heat dissipation fins: For most miniature stepper motors (especially NEMA 17), sticking or clamping aluminum alloy heat dissipation fins on the motor housing is the most direct and economical method. The heat sink greatly increases the heat dissipation surface area of the motor, utilizing natural convection of air to remove heat.

Forced air cooling: If the heat sink effect is still not ideal, especially in enclosed spaces, adding a small fan (such as 4010 or 5015 fan) for forced air cooling is the ultimate solution. Airflow can quickly carry away heat, and the cooling effect is extremely significant. This is the standard practice on 3D printers and CNC machines.

Solution 4: Optimize Drive Settings (Advanced Techniques)

Many modern intelligent drives, offer advanced current control functionality:

StealthShop II&SpreadCycle: With this feature enabled, when the motor is stationary for a period of time, the driving current will automatically decrease to 50% or even lower of the operating current. Due to the motor being in a hold state for most of the time, this function can significantly reduce static heating.

Why it works: Intelligent management of current, providing sufficient power when needed, reducing waste when not needed, and directly saving energy and cooling from the source.

Solution 5: Check the mechanical structure and reselect (fundamental solution)

Mechanical inspection: Manually rotate the motor shaft (in power-off state) and feel if it is smooth. Check the entire transmission system to ensure there are no areas of tightness, friction, or jamming. A smooth mechanical system can greatly reduce the burden on the motor.

Re selection: If after trying all the above methods, the motor is still hot and the torque is barely enough, then it is likely that the motor has been selected too small. Replacing the motor with a larger specification (such as upgrading from NEMA 17 to NEMA 23) or a higher rated current, and allowing it to operate within its comfort zone, will naturally fundamentally solve the heating problem.

Follow the process to investigate:

Facing a micro stepper motor with severe heating, you can systematically solve the problem by following the following process:

Motor is overheating severely

Step 1: Check if the drive current is set too high?

Step 2: Check if the mechanical load is too heavy or friction is high?

Step 3: Install physical cooling devices

Attach a heat sink

Add forced air cooling (small fan)

Has the temperature improved?

Step 4: Consider reselecting and replacing with a larger motor model

Post time: Sep-28-2025