1.What is stepper motor?

Stepper motors move differently than other motors. DC stepper motors use discontinuous movement. There are multiple coil groups in their bodies, called "phases", which can be rotated by activating each phase in sequence. One step at a time.

By controlling the stepper motor via the controller / computer, you can position accurately at a precise speed. Because of this advantage, stepper motors are often widely used in equipment that requires precise motion.

Stepper motors have multiple different sizes, shapes and designs. This article will specifically explain how to choose a stepper motor according to your needs.

2. What are the advantages of stepper motors?

A. Positioning - Because the movement of stepper motors is precise and repetitive, they can be used in a variety of precisely controlled products, such as 3D printing, CNC, camera platform, etc., some hard drives also use step Motor for positioning the read head

B. Speed control - precise steps also mean that you can precisely control the speed of rotation, suitable for performing precise actions or robot control

C. Low speed and high torque - In general, DC motors have low torque at low speeds. But stepper motors have maximum torque at low speeds, so they are a good choice for low-speed high-precision applications.

3. Disadvantages of stepper motor :

A. Inefficiency - Unlike DC motors, the consumption of stepper motors is not much related to the load. When they are not doing work, there is still current through, so they usually have overheating problems, and the efficiency is more low

B. Torque at high speed - usually the torque of the stepper motor at high speed is lower than at low speed, some motors can still achieve better performance at high speed, but this requires a better drive to achieve this effect

C. Unable to monitor - ordinary stepper motors cannot feedback / detect the current position of the motor, we call it "open loop", if you need "closed loop" control, you need to install an encoder and driver, so that you can Monitor / control the precise rotation of the motor at any time, but the cost is very high and it is not suitable for ordinary products

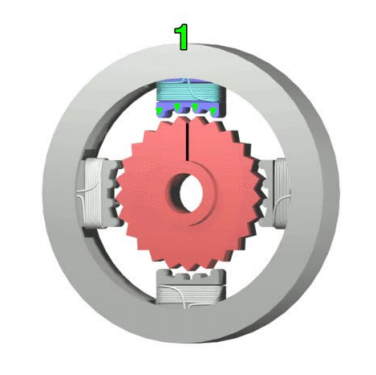

Stepping Motor Phase

4. Classification of stepping:

There are many types of stepper motors, suitable for various situations.

However, under normal circumstances, PM motors and hybrid stepper motors are generally used without considering private server motors.

5. Motor size:

The first consideration when choosing a motor is the size of the motor. Stepper motors range from 4mm miniature motors (used to control the movement of cameras in smartphones) to behemoths like NEMA 57.

The motor has a working torque, this torque determines whether it can meet your demand for motor power.

For example: NEMA17 is generally used in 3D printers and small CNC equipment, and larger NEMA motors are used in industrial production.

NEMA17 here refers to the outer diameter of the motor is 17 inches, which is the size of the inch system, which is 43cm when converted to centimeters.

In China, we generally use centimeters & millimeters to measure dimensions, not inches.

6. Number of motor steps:

The number of steps per motor revolution determines its resolution and accuracy. Stepper motors have steps from 4 to 400 per revolution. Usually 24, 48 and 200 steps are used.

Accuracy is usually described as the degree of each step. For example, the step of a 48-step motor is 7.5 degrees.

However, the drawbacks of high precision are speed and torque. At the same frequency, the speed of high-precision motors is lower.

7. Gear box:

Another way to improve accuracy and torque is to use a gearbox.

For example, a 32: 1 gearbox can convert an 8-step motor to a 256-step precision motor, while increasing the torque by 8 times.

But the output speed will be correspondingly reduced to one-eighth of the original.

A small motor can also achieve the effect of high torque through the reduction gearbox.

8. Shaft:

The last thing you need to consider is how to match the drive shaft of the motor and how to match your drive system.

The types of shafts are:

Round shaft / D shaft: This type of shaft is the most standard output shaft, used to connect pulleys, gear sets, etc. The D shaft is more suitable for high torque to prevent slipping.

Gear shaft: The output shaft of some motors is a gear, which is used to match a specific gear system

Screw shaft: A motor with a screw shaft is used to construct a linear actuator, and a slider can be added to achieve linear control

Please feel free to contact us if you are interested in any of our stepper motors.

Post time: Jan-29-2022