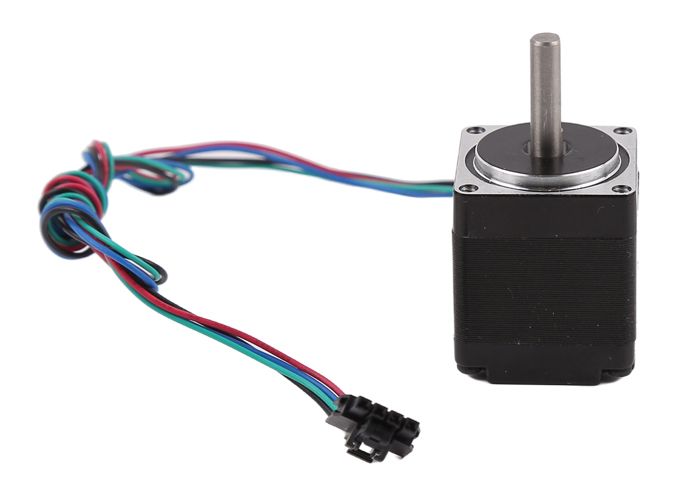

Stepper motors are discrete motion devices with a low cost advantage over servo motors are devices that convert mechanical and electrical energy. A motor that converts mechanical energy into electrical energy is called a "generator"; a motor that converts electrical energy into mechanical energy is called a "motor". Stepper motors and servo motors are motion control products that can precisely locate the movement of automation equipment and the way it moves, and are mainly used in the manufacturing of automation equipment.

There are three types of stepper motor rotor: reactive (VR type), permanent magnet (PM type) and hybrid (HB type). 1) Reactive (VR type): gear with rotor teeth. 2) Permanent magnet (PM type): rotor with permanent magnet. 3) Hybrid (HB type): gear with both permanent magnet and rotor teeth. Stepper motors are classified according to the windings on the stator: there are two-phase, three-phase and five-phase series. Motors with two stators become two-phase motors and those with five stators are called five-phase motors. The more phases and beats a stepper motor has, the more accurate it is.

HB motors can achieve very precise small incremental step motion, while PM motors generally do not require high control accuracy. HB motors can achieve complex, precise linear motion control requirements. PM motors are relatively small in torque and volume, generally do not require high control accuracy, and are more economical in cost. Industries: textile machinery, food packaging. In terms of production process and motor control accuracy, HB stepper motors are more high-end than PM stepper motors.

Stepper motors and servo motors are both motion control products, but differ in their product performance. A stepper motor is a discrete motion device that receives a command and executes a step. Stepper motors convert the input pulse signal into an angular displacement. When the stepper motor driver receives a pulse signal, it drives the stepper motor to rotate by a fixed angle in the set direction. A servo motor is a servo system in which electrical signals are converted into torque and speed to drive a control object, which can control speed and position accuracy.

✓ Stepper motors, servo motors are quite different in terms of low frequency characteristics, moment frequency characteristics and overload capacity:.

Control accuracy: the more phases and rows of stepper motors, the higher the accuracy; the control accuracy of AC servo motors is guaranteed by the rotary encoder at the back end of the motor shaft, the more encoder scales, the higher the accuracy.

✓ Low-frequency characteristics: stepper motors are prone to low-frequency vibration phenomenon at low speeds, this low-frequency vibration phenomenon determined by the working principle of stepper motors is detrimental to the normal operation of the machine, and generally use damping technology to overcome the low-frequency vibration phenomenon; AC servo systems have resonance suppression function, which can cover the lack of rigidity of the machinery. The operation is very smooth and no vibration phenomenon occurs even at low speeds.

✓ Torque-frequency characteristics: the output torque of stepper motors decreases with increasing speed, so their maximum operating speed is 300-600RPM; servo motors can output rated torque up to rated speed (generally 2000-3000RPM), and above rated speed is constant power output.

✓ Overload capability: stepper motors do not have overload capability; servo motors have strong overload capability.

✓ Response performance: stepper motors take 200-400 ms to accelerate from standstill to operating speed (several hundred revolutions per minute); AC servo has better acceleration performance and can be used in control situations requiring fast start/stop. The Panasonic MASA 400W AC servo, for example, accelerates from standstill to its rated speed of 3000RPM in just a few milliseconds.

Operational performance: stepper motors are open-loop controlled, and are prone to step loss or blocking when the starting frequency is too high or the load is too large, and to overshoot when the speed is too high when stopping; AC servo is closed-loop controlled, and the driver can directly sample the motor encoder feedback signal, so there is generally no step loss or overshoot of the stepper motor, and the control performance is more reliable.

AC servo is better than stepper motor in terms of performance, but stepper motor has the advantage of low price. AC servo is superior to stepper motors in terms of response speed, overload capacity and running performance, but stepper motors are used in some less demanding scenarios due to their cost-performance advantage. With the use of closed-loop technology, closed-loop stepper motors can provide excellent accuracy and efficiency, which can achieve some of the performance of servo motors, but also has the advantage of low price.

Look ahead and lay out emerging areas. Stepper motor applications have undergone structural changes, with the traditional market reaching saturation and new industries emerging. The company's control motors and drive system products are deeply laid out in medical instruments, service robots, industrial automation, information and communication, security and other emerging industries, which account for a relatively large share of the overall business and are growing at a fast rate. The demand for stepper motors is related to the economy, technology, the level of industrial automation and the level of technical development of stepper motors themselves. The market has reached saturation in traditional industries such as office automation, digital cameras and household appliances, while new industries continue to emerge, such as 3D printing, solar power generation, medical equipment and automotive applications.

| Fields | Specific applications |

| Office automation | Printers, scanners, copiers, MFPs, etc. |

| Stage Lighting | Light direction control, focus, colour shift, spot control, lighting effects, etc. |

| Banking | ATM machines, bill printing, bank card production, money counting machines, etc. |

| Medical | CT scanner, haematology analyser, biochemistry analyser, etc. |

| Industrial | Textile machinery, packaging machinery, robots, conveyors, assembly lines, placement machines, etc. |

| Communication | Signal conditioning, mobile antenna positioning, etc. |

| Security | Motion control for surveillance cameras. |

| Automotive | Oil/gas valve control, light steering system. |

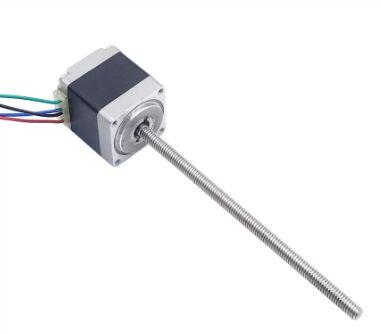

Emerging Industry 1: 3D printing continues to make breakthroughs in R&D technology and broaden the application scenarios in the downstream, with domestic and international markets growing at a rate of approximately 30%. 3D printing is based on digital models, stacking materials layer by layer to create physical objects. The motor is an important power component on the 3D printer, the accuracy of the motor affects the effect of 3D printing, generally 3D printing using stepper motors. 2019, the global 3D printing industry scale of $12 billion, an increase of 30% year-on-year;.

Emerging industry 2: Mobile robots are computer-controlled, with functions such as movement, automatic navigation, multi-sensor control, network interaction, etc. The most important use in practical production is handling, with a high degree of non-standardisation.

Stepper motors are used in the drive module of mobile robots, and the main drive structure is assembled from drive motors and reduction gears (gearboxes). Although the domestic industrial robot industry started late compared to foreign countries, it is ahead of foreign countries in the field of mobile robots. At present, the core components of mobile robots are mainly domestically produced, and domestic enterprises have basically reached the accuracy requirements in all aspects, and there are fewer foreign competing enterprises.

China's mobile robot market size will be approximately $6.2 billion in 2019, up 45% year-on-year. International launch of professional cleaning robots with significant increase in cleaning efficiency. The launch of the "second robot" in 2018 follows the launch of the humanoid robot. The "second robot" is an intelligent commercial vacuuming robot with multiple sensors to detect obstacles, stairs and human movement. It can run for three hours on a single charge and can clean up to 1,500 square metres. The "second robot" can replace most of the cleaning staff's daily workload and can increase the frequency of vacuuming and cleaning in addition to the existing cleaning work.

Emerging industry 3: With the introduction of 5G, the number of antennas for communication base stations is increasing and the number of motors required is also increasing. In general, 3 antennas are required for ordinary communication base stations, 4-6 antennas for 4G base stations, and further increases in the number of base stations and antennas for 5G applications as they need to cover traditional mobile phone communication and IoT communication applications. Control motor products with gearbox components are becoming a mainstream custom development for base station antenna plants. One control motor with gearbox is used for each ESC antenna.

The number of 4G base stations increased by 1.72 million in 2019, and 5G construction is expected to open a new cycle. 2019, the number of mobile phone base stations in China reached 8.41 million, of which 5.44 million were 4G base stations, accounting for 65%. 2019, the number of new 4G base stations increased by 1.72 million, the most since 2015, mainly due to 1) network expansion to cover blind spots in rural areas. 2) The core network capacity will be upgraded to lay the foundation for 5G network construction. China's 5G commercial licence will be issued in June 2019, and by May 2020, more than 250,000 5G base stations will be opened nationwide.

Emerging Industry 5: Medical devices are one of the main application scenarios for stepper motors and are one of the segments that Vic-Tech is deeply involved in. From metal to plastic, medical devices require a high level of precision in their production. Many medical device manufacturers use servo motors to meet the accuracy requirements, but because stepper motors are more economical and smaller than servos, and the accuracy can meet some medical devices, stepper motors are used in the medical device manufacturing industry and even replace some servo motors.

Post time: May-19-2023