Stepper motors are electromechanical devices that directly convert electrical impulses into mechanical motion. By controlling the sequence, frequency and number of electrical impulses applied to the motor coils, stepper motors can be controlled for steering, speed and angle of rotation. Without the aid of a closed-loop feedback control system with position sensing, precise position and speed control can be achieved by using a simple, low-cost open-loop control system consisting of a stepper motor and its accompanying driver.

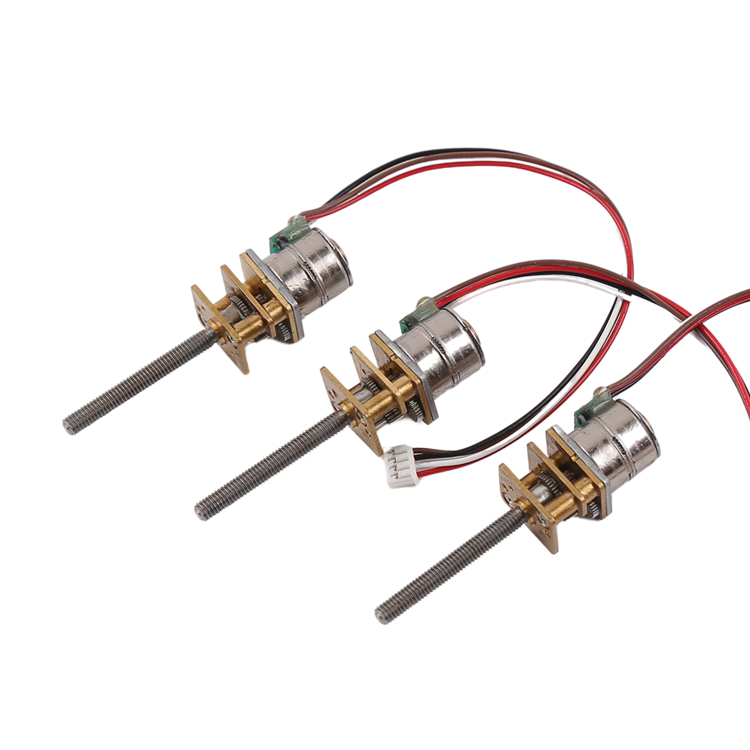

Stepping motor as an executive element, is one of the key products of mechatronics, widely used in various automation control systems. With the development of microelectronics technology and precision manufacturing technology, the demand for stepper motors is increasing day by day, and stepper motors and gear transmission mechanism combined with gearboxes, also in more and more application scenarios to see, today and everyone to understand this type of gearbox transmission mechanism.

How to decelerate stepper motor?

As a commonly used and widely used drive motor, stepper motor is usually used together with deceleration equipment to achieve the ideal transmission effect; and the commonly used deceleration equipment and methods for stepper motor are such as deceleration gearboxes, encoders, controllers, pulse signals and so on.

Pulse signal deceleration: stepper motor speed, is based on the input pulse signal changes to change. Theoretically, give the driver a pulse, the stepper motor rotates a step angle (subdivided for a subdivided step angle). In practice, if the pulse signal changes too quickly, the stepper motor, due to the damping effect of the internal reverse electromotive force, the magnetic reaction between the rotor and the stator will not be able to follow the changes in the electrical signal, which will lead to blocking and step loss.

Reduction gear box deceleration: stepper motor equipped with a reduction gear box used together, the stepper motor output high speed, low torque speed, connected to the reduction gear box, gear box internal reduction gears mesh transmission formed by the reduction ratio, the stepper motor output of high speed reduction, and enhance the transmission torque, to achieve the ideal transmission effect; deceleration effect depends on the gear box reduction ratio, the greater the reduction ratio, the smaller the output speed, and vice versa. The effect of deceleration depends on the gearbox reduction ratio, the larger the reduction ratio, the smaller the output speed and vice versa.

Curve exponential control speed: exponential curve, in the software programming, the first calculation of the time constant stored in the computer memory, work pointing to the selection. Usually, the acceleration and deceleration time to complete the stepper motor is more than 300ms. If you use too short acceleration and deceleration time, for the vast majority of stepper motors, it will be difficult to achieve high-speed rotation of the stepper motor.

Encoder-controlled deceleration: PID control, as a simple and practical control method, has been widely used in stepper motor drives. It is based on the given value r ( t ) and the actual output value c ( t ) constitutes the control deviation e ( t ), the deviation of the proportional, integral and differential through a linear combination of the control quantity, the controlled object control. The integrated position sensor is used in a two-phase hybrid stepper motor, and an auto-adjustable PI speed controller is designed on the basis of position detector and vector control, which can provide satisfactory transient characteristics under variable operating conditions. According to the mathematical model of the stepper motor, the PID control system of the stepper motor is designed, and the PID control algorithm is used to obtain the control quantity, so as to control the motor to move to the specified position.

Finally, the control is verified by simulation to have good dynamic response characteristics. The use of PID controller has the advantages of simple structure, robustness, reliability and so on, but it can not effectively deal with the uncertain information in the system.

Post time: Apr-07-2024