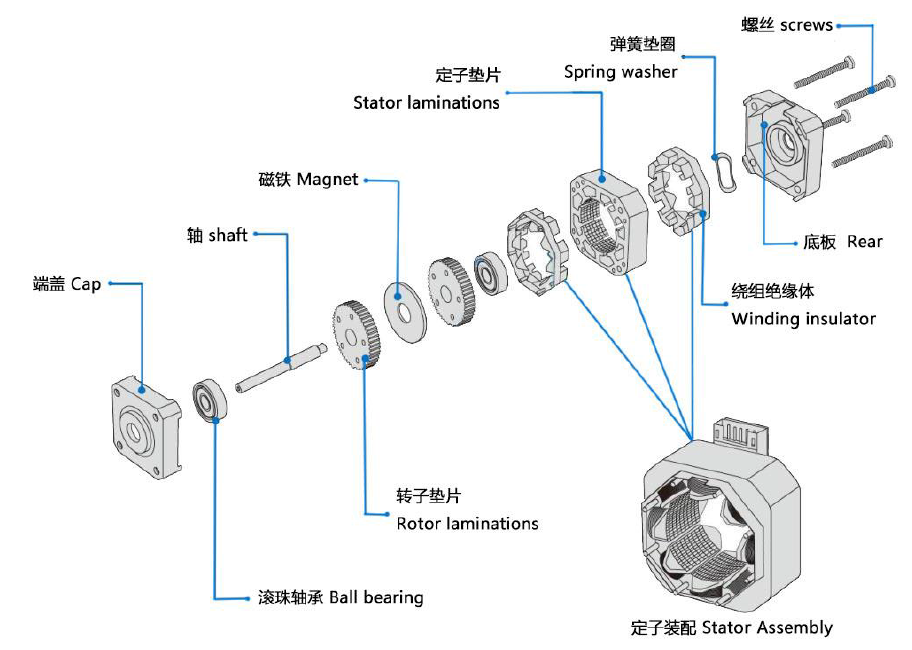

Stepper motor is an electromechanical device that directly converts electrical pulses into mechanical motion. By controlling the sequence, frequency and number of electrical pulses applied to the motor coil, the stepper motor's steering, speed and rotation angle can be controlled. Accurate position and speed control can be achieved without the use of a closed-loop feedback control system with position sensing, using a simple, low-cost open-loop control system with a stepper motor and its accompanying driver.

As an actuator, stepper motor is one of the key products of mechatronics, which is widely used in various automation control systems. With the development of microelectronics and precision manufacturing technology, the demand for stepper motors is increasing day by day, and stepper motors and gear transmission mechanism combined into a reduction gear box, but also in more and more application scenarios to see, today small and everyone together to understand this type of reduction gear transmission mechanism.

How do stepper motors decelerate?

Stepper motor as a commonly used, widely used drive motor, usually used with deceleration equipment to achieve the ideal transmission effect; and stepper motor commonly used deceleration equipment and methods, such as reduction gear box, encoder, controller, pulse signal, etc..

Pulse signal deceleration: stepper motor rotation speed, is based on the change of the input pulse signal to change. In theory, give the driver a pulse, the stepper motor rotates a step angle (subdivision for a subdivision step angle). In practice, if the pulse signal changes too quickly, the stepper motor due to the internal damping effect of the reverse electric potential, the magnetic response between the rotor and stator will not follow the change in the electrical signal, will lead to blocking and lost steps.

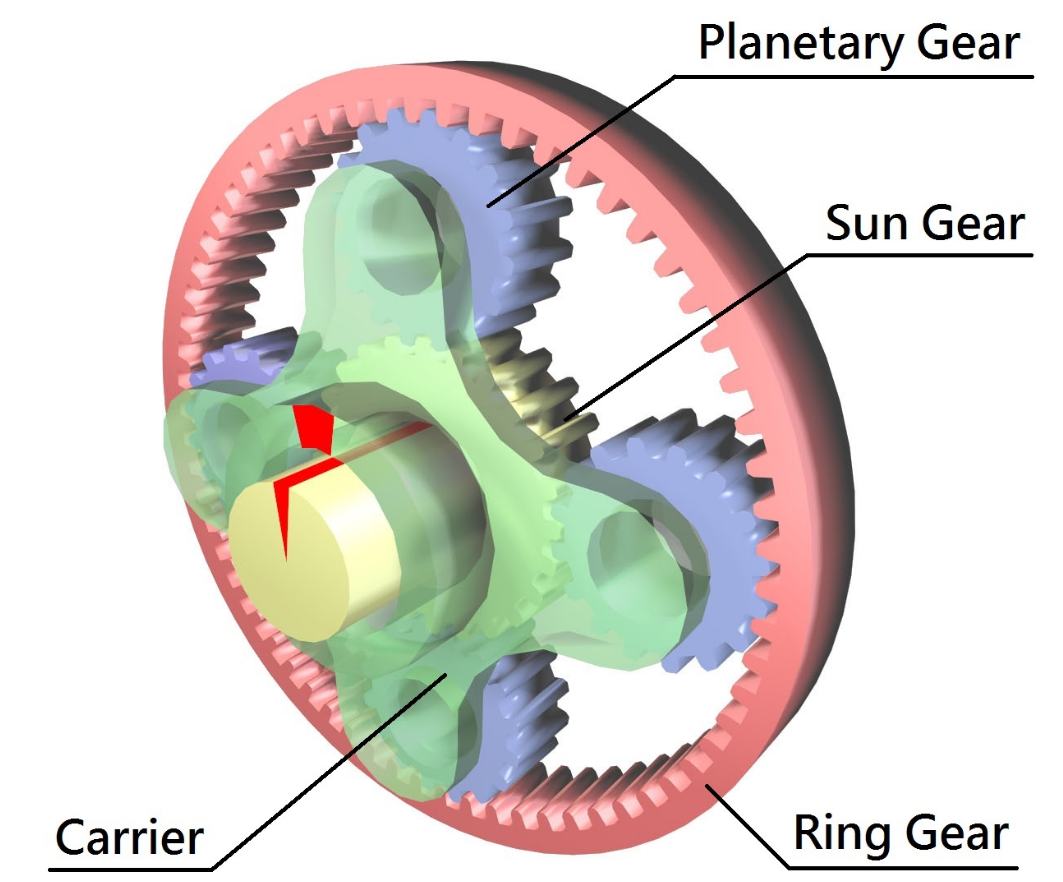

Reduction gearbox deceleration: stepper motor equipped with a reduction gearbox used together, stepper motor output high speed, low torque speed, connected to the reduction gearbox, gearbox internal reduction gear set meshing transmission formed by the reduction ratio, the stepper motor output high speed will be reduced, and enhance the transmission torque to achieve the ideal transmission effect; reduction effect depends on the gearbox reduction ratio, the greater the reduction ratio, the smaller the output speed, and vice versa. And vice versa.

Curve exponential control speed: exponential curve, in the software programming, first calculated time constants stored in the computer memory, point to the selection when working. Usually, the completion of the stepper motor acceleration and deceleration time of 300ms or more. If you use too short acceleration and deceleration time, for the vast majority of stepper motors, it will be difficult to achieve high-speed rotation of stepper motors.

Encoder control deceleration: PID control as a simple and practical control method , in the stepper motor drive has gained wide application. It is based on the given value r ( t ) and the actual output value c ( t ) to form the control deviation e ( t ) , the deviation of the proportional , integral and differential through a linear combination of the control quantity , the control object control . The paper uses an integrated position sensor in a two-phase hybrid stepper motor and designs an automatically adjustable PI speed controller based on a position detector and vector control, which provides satisfactory transient characteristics under variable operating conditions. Based on the mathematical model of the stepper motor, the PID control system of the stepper motor is designed and the PID control algorithm is used to obtain the control quantity to control the motor movement to the specified position. Finally, it is verified by simulation that the control has good dynamic response characteristics. The PID controller has the advantages of simple structure, high robustness and high reliability, but it cannot effectively deal with the uncertain information in the system.

Stepper motor can be matched with what reducer? In the stepper motor and gearbox selection package need to pay attention to those factors, and what kind of gearbox can be selected for use together?

1. The reason for stepper motor with reducer

Stepper motor switch the frequency of the stator phase current, such as changing the input pulse of the stepper motor drive circuit, so that it becomes a low-speed movement. Low-speed stepper motor in waiting for the stepping command, the rotor is at a stop, in the low-speed stepping, speed fluctuations will be very large, at this time, such as changing to high-speed operation, it can solve the problem of speed fluctuations, but the torque will be insufficient. That is, the low speed will torque fluctuations, and the high speed will be insufficient torque, the need to use the reducer.

2. Stepper motor often with reducer what

Reducer is a kind of gear drive, worm drive, gear - worm drive, which is enclosed in a rigid casing, is often used as a reducer between the prime mover and the work machine, between the prime mover and the work machine or actuator to match the speed and torque transmission; reducer has a wide range, according to the type of transmission can be divided into gear reducer, worm gear reducer and planetary gear reducer. According to the number of transmission stages can be divided into single-stage and multi-stage reducer; according to the shape of the gear can be divided into cylindrical gear reducer, bevel gear reducer and bevel-cylindrical gear reducer; according to the transmission arrangement form can be divided into unfolded reducer, shunt reducer and coaxial reducer. Stepper motor assembly reducer are planetary reducer, worm gear reducer, parallel gear reducer, filament gear reducer.

What about stepper motor planetary reducer accuracy?

The accuracy of reducer is also called return clearance. When the output end is fixed and the input end is rotated clockwise and counterclockwise to produce the rated torque +-2% torque at the output end, there is a small angular displacement at the input end of the reducer, and this angular displacement is the return clearance. The unit is "arc minutes", i.e. one sixtieth of a degree. The usual return clearance values refer to the output side of the gearbox. Stepper motor planetary reducer has high rigidity, high precision (single stage can be achieved within 1 minute), high transmission efficiency (single stage in 97%-98%), high torque/volume ratio, maintenance-free, etc.

Stepper motor transmission accuracy is not adjustable, stepper motor running angle is determined entirely by the step length and the number of pulses, and the number of pulses can be a complete count, the digital quantity is not the concept of accuracy, one step is one step, two steps is two steps. The current accuracy that can be optimized is the accuracy of the gear return clearance of the planetary gearbox.

- Spindle accuracy adjustment method: the adjustment of the planetary gearbox spindle rotational accuracy, if the machining error of the spindle itself meets the requirements, then the rotational accuracy of the reducer spindle is generally determined by the bearing. The key to adjusting the spindle rotation accuracy is to adjust the bearing clearance. Maintaining a suitable bearing clearance is critical to the performance of the spindle components and bearing life. For rolling bearing, when there is a large clearance, it will not only make the load concentrated on the rolling body in the direction of force, but also produce serious stress concentration phenomenon in the bearing inner and outer ring raceway contact, shorten the bearing life, also make the spindle centerline drift, easy to cause vibration of the spindle parts. Therefore, the rolling bearing adjustment must be pre-loaded, To produce a certain amount of interference inside the bearing, so as to produce a certain elastic deformation at the contact between the rolling body and the inner and outer ring raceway, thus improving the stiffness of the bearing.

2. Adjustment gap method: planetary gearbox in the process of movement will produce friction, causing changes in size, shape and surface quality between the parts, and wear, so that the gap between the parts with increased, we need to make a reasonable range of adjustment to ensure the accuracy of the relative movement between the parts.

3. Error compensation method: the parts themselves error through the appropriate assembly, so that the phenomenon of mutual offset during the break-in period, to ensure the accuracy of the equipment movement trajectory.

- Comprehensive compensation method: the tool installed with the reducer itself to make the processing has been transferred with the correct adjustment of the work table to eliminate the combined results of the accuracy of the errors.

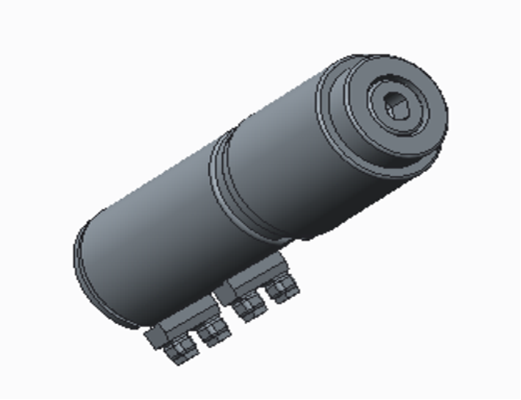

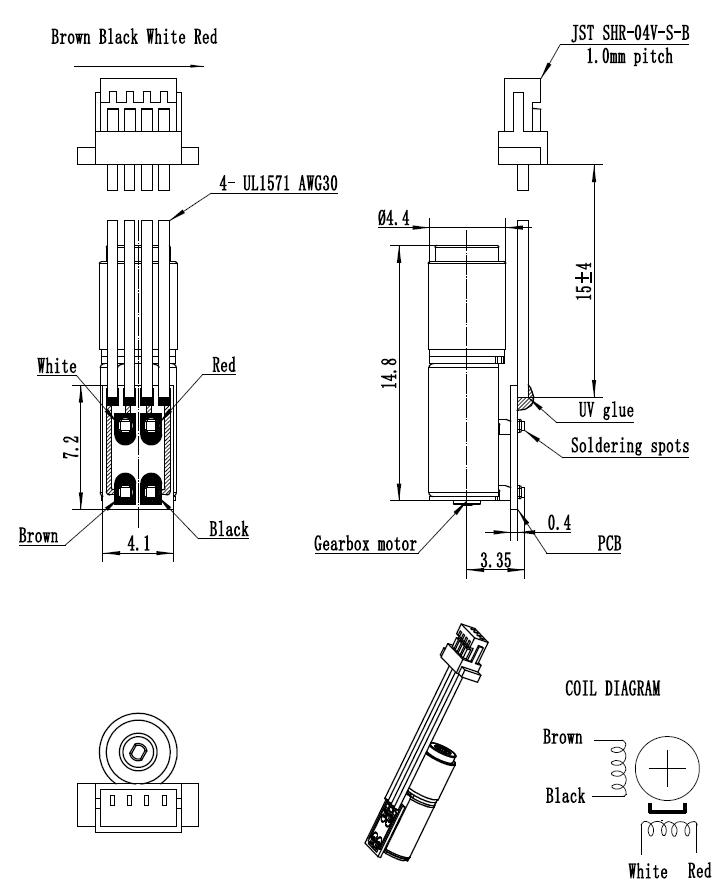

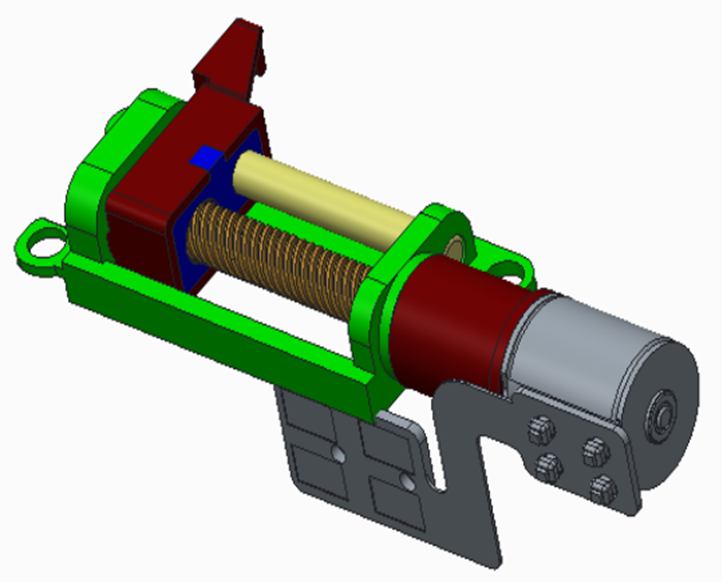

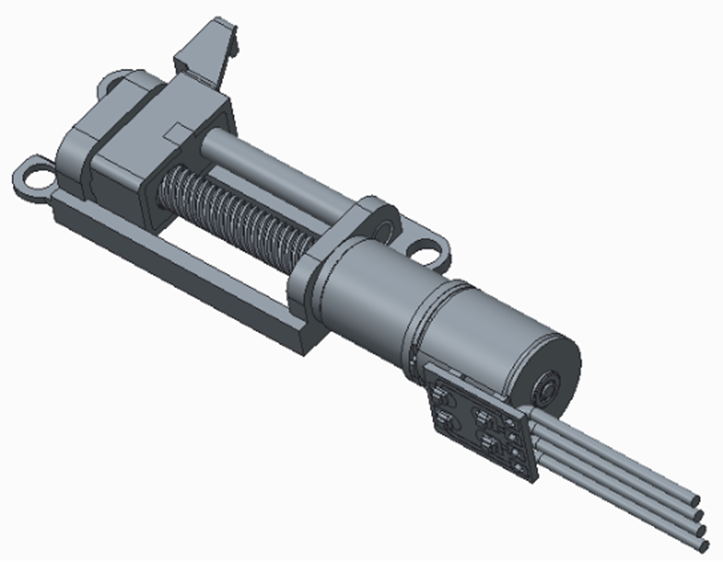

Our custom projects 1.

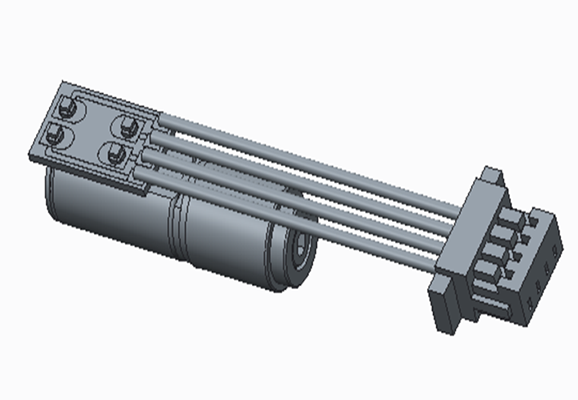

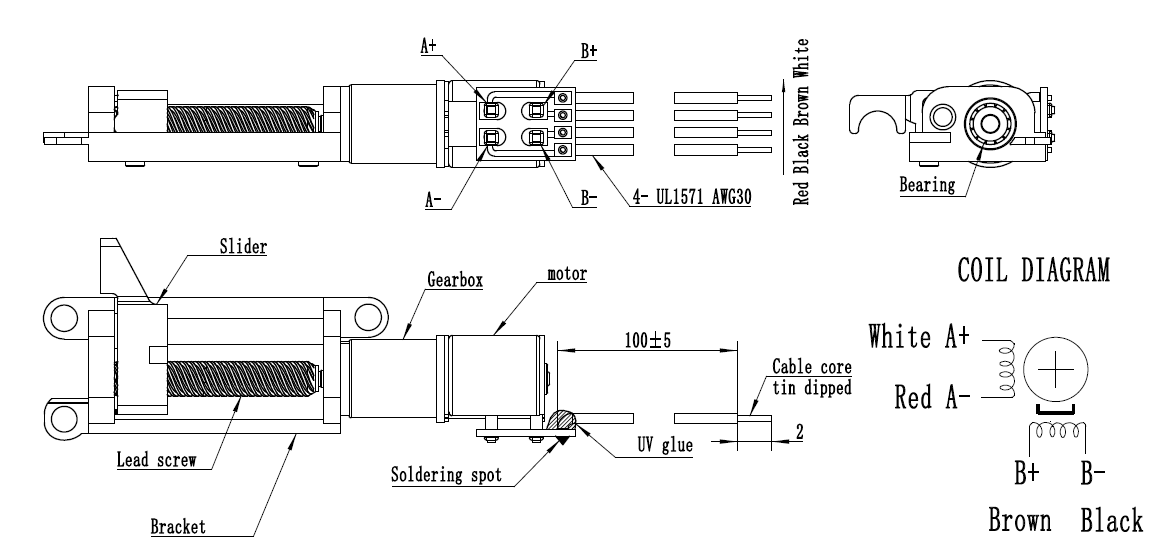

Our custom projects 2.

We are a professional research and production organization focusing on motor research and development, overall solutions for motor applications, and processing and production of motor products. Our company has specialized in manufacturing micro motors and accessories since 2011. Our main products: miniature stepper motors, gear motors, underwater thrusters and motor drivers and controllers.

Our products have passed ISO9000:200, ROHS, CE and other quality system certifications. Our company has applied for more than 20 patents, including 3 invention patents, which are widely used in financial machinery, office automation, electronic door locks, electric curtains, intelligent toys, medical machinery, vending machines, amusement equipment, advertising equipment, security equipment, stage lighting, automatic mahjong machines, bathroom appliances, (personal care beauty and hairdressing equipment, massage equipment, hairdryer, auto parts, toys, power tools, small household appliances, etc.) well-known manufacturers. The company has strong technical force, advanced equipment, adhere to the "market-oriented, quality as the core, reputation for development" business purposes, to strengthen internal management, improve product quality.

We interact closely with our customers, listen to their needs and act according to their requirements. We believe that the basis of win-win partnership is product quality and customer service.

Feel free to communicate with us!

Post time: Nov-24-2022