Micro geared motor noise analysis

How is the noise of the micro geared motor generated? How to reduce or prevent the noise in daily work, and how to solve this problem? Vic-tech motors explain this problem in detail:

1. Gear precision: Is the gear precision and fit OK?

2. Gear clearance: Is the clearance between the gears qualified? Large gap load sound is greater.

3. motor itself whether noise: precision motor, the noise itself is small, some imported motor, noise itself is small, poor quality motor itself is noisy.

4. gear lubricant: whether the amount of oil is not enough, at the beginning of the operation can but after a long time can not play a lubricating effect, of course, there will be abnormalities.

5. Whether the installation is reasonable: whether there is a suitable sound insulation device between the motor and the metal contact surface, in order to avoid resonance noise.

6. Whether the motor selection is reasonable: To choose according to the actual situation of the load installation, find the motor with matching power, and try not to overload the motor.

7. Gear material selection: plastic teeth lower noise, but the load capacity is not strong. Steel gears are relatively noisy but have a strong load capacity.

Motor installation requires special attention to the following.

1, output shaft: Please do not rotate the gear motor from the output shaft direction

* gear head will become a speed increasing mechanism, resulting in internal damage to gears and so on, resulting in micro geared motors become generators.

2 installation position: the standard installation position is horizontal.

* When used in other direction position, it may cause the micro geared motor lubricating oil leakage, load changes, so as to change the characteristics of the horizontal direction with changes

3, processing: Please do not perform any kind of processing on the wheel outlet shaft.

*The load, impact, cutting powder, etc. during processing may cause damage to the product.

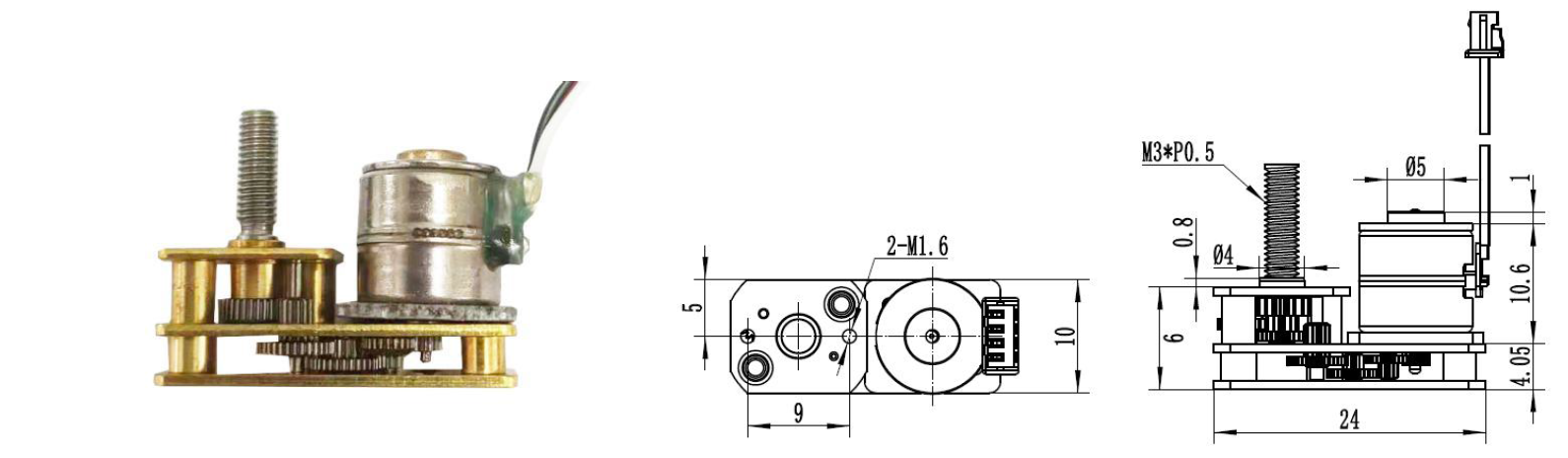

4、Screws: Please check the form and length size shown in the appearance drawing before installing screws.

*When installing the miniature gear motor, the screws are too long and the fixed studs are too large will cause deformation and damage to the internal parts of the mechanism, and the deformation of the screws themselves will lead to accidents. In addition, when the fixing screw column is too weak, it may also cause instability or fall off, please pay attention when using.

5、Installation of output shaft: Please use adhesive carefully.

*Please be careful not to let the adhesive flow from the output shaft into the shaft. In particular, volatile adhesives such as silicone adhesives may cause adverse effects inside the miniature geared motor, so please avoid using them, and avoid excessive pressure to prevent deformation and breakage of the internal mechanism.

6, miniature geared motor terminal processing: welding work please implement in a short time. (Recommended: the temperature of the welding head 340~400 degrees, within 2 seconds)

*Overheating of the terminal will cause the dissolution of the micro geared motor parts and produce the effect of poor internal structure. In addition, applying pressure to the terminal part will increase the internal burden of the miniature geared motor. Causing the internal breakage of the miniature geared motor.

7, Lubricant: Apply to the sliding part of the gear.

*Please be careful when using it in special environment, as it may bleed to the outside according to the structure characteristics of micro geared motor.

8、Using environment tolerance range? Please use within the range of -10℃~+50℃, and humidity 30%~90% cannot be exposed.

*When used in temperatures outside the specified range, the lubricant of the gear head will not function properly and the micro geared motor will not start. (If different temperature conditions are required, we can change the lubricant and micro geared motor parts. Please contact us if you need more information.)

9. Allowable range of storage environment Please store within the range of -20℃~65℃. Humidity 10%~95% without condensation

*If stored outside the temperature range, the lubricant of the gear head will not function and the micro geared motor will not start.

10,Corrosion: Please avoid storing the product in the environment containing corrosive gas, toxic gas, high temperature, low temperature and high humidity.

11,Service life? The life span of the micro geared motor varies greatly depending on the load conditions, operation mode, and use environment. Please be sure to test the product to see if it works. The following conditions are the reasons that affect the service life of the micro geared motor. Please communicate with us when using them.

①Use of load exceeding the rated torque

②Frequent starting

③ Instantaneous reversal in forward and reverse directions

④Impact loading

⑤Long time continuous operation

⑥Forced return to the output shaft

⑦Exceeding the load weight allowed by the protruding suspension, exceeding the use of the allowable thrust load

⑧Pulse drive for braking, reverse start current, PWM braking, etc.

⑨ Use of voltage outside the standard rated specifications

⑩Exceed the operating temperature range, relative humidity range, or use in special environments.

For other applications and environments, please consult with us. We will select the appropriate model according to your needs.

*Please note:

a. The assembled gearbox should not be disassembled at will to avoid noise or quality problems caused by poor gear bite.

b. When connecting the output shaft with the load, please do not knock or squeeze it arbitrarily. To avoid quality problems such as axis offset or jamming.

Above, for reference. Please understand if there are any shortcomings! Also contact the engineer we will answer for you in the shortest time!

Post time: Nov-25-2022