This article mainly discusses DC motors, geared motors, and stepper motors, and servo motors refer to DC micro motors, which we usually come across mostly. This article is only for beginners to talk about the various motors commonly used to make robots.

A motor, commonly known as a "motor", is an electromagnetic device that converts or transmits electrical energy according to the laws of electromagnetic induction. An electric motor, also known as a motor, is represented in the circuit by the letter "M" (the old standard was "D"). Its main function is to produce driving torque as a power source for appliances or various machines, and the generator is represented by the letter "G" in the circuit.

Miniature DC Motor

Miniature DC motor is our flat time more motors, electric toys, razors, etc. are inside. This motor has too fast speed, torque is too small, generally only two pins, with the positive and negative battery connected to the two pins will turn up, and then the positive and negative battery and then the opposite of the two pins connected to the motor will also turn in the opposite direction.

Miniature DC motors on toy cars

Micro Geared Motor

Miniature geared motor is a miniature DC motor with a gearbox, which reduces the speed and increases the torque, making the miniature motor more widely used.

Micro-gear geared motor

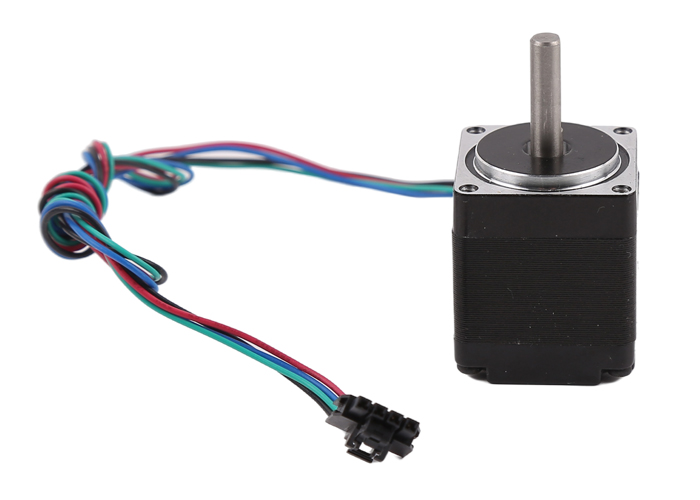

Micro Stepper Motor

Stepper motor is an open-loop control element stepper motor device that converts electrical pulse signals into angular or linear displacements. In the case of non-overload, the motor speed, stop position only depends on the frequency of the pulse signal and the number of pulses, and is not affected by changes in load, when the stepper driver receives a pulse signal, it drives the stepper motor to turn a fixed angle in the direction set, called the "step angle", its rotation is to a fixed angle Step by step operation. The number of pulses can be controlled to control the amount of angular displacement, so as to achieve the purpose of accurate positioning; at the same time, the pulse frequency can be controlled to control the speed and acceleration of motor rotation, so as to achieve the purpose of speed regulation.

Micro Stepper Motor

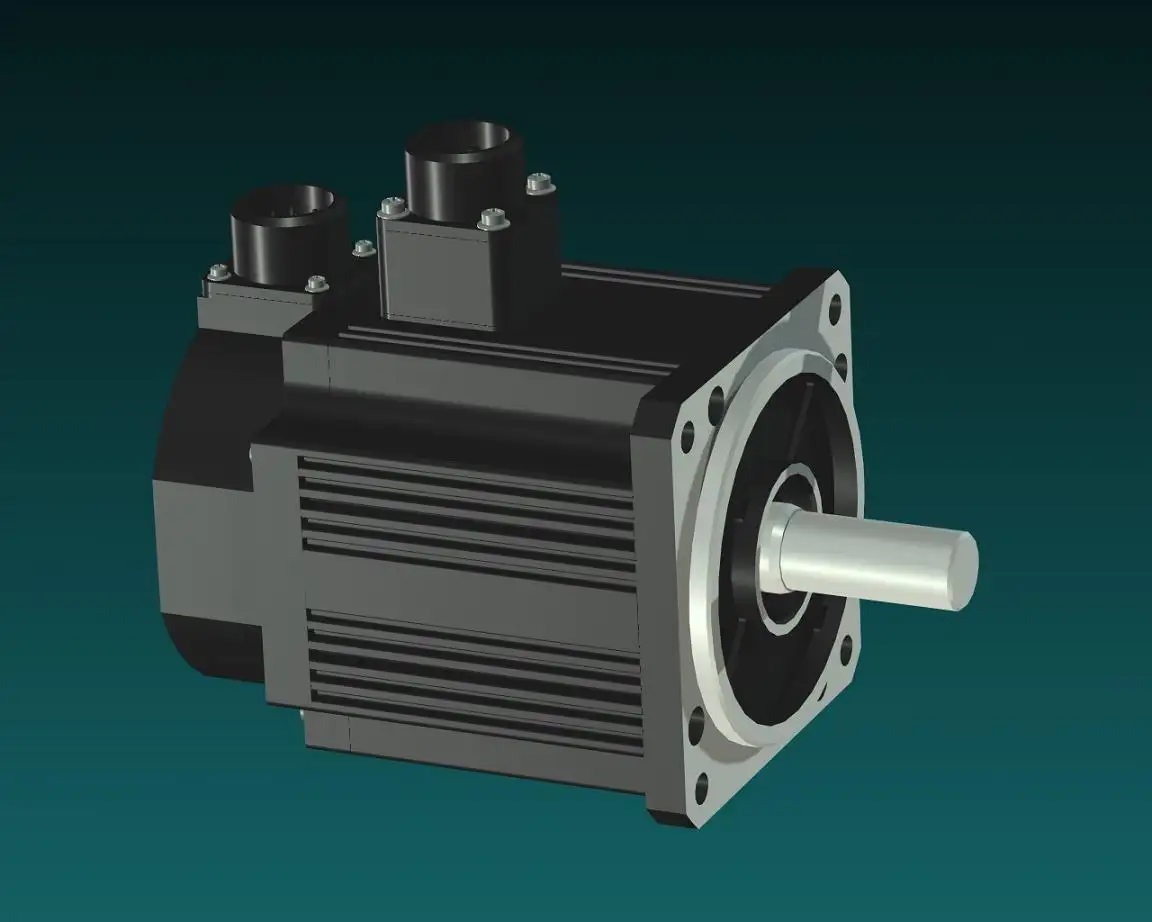

Servo motor

Servo mainly relies on pulses for positioning, basically, you can understand it this way, the servo motor receives 1 pulse, it will rotate 1 pulse corresponding to the angle, so as to achieve displacement, because, the servo motor itself has the function of sending out pulses, so the servo motor will send out the corresponding number of pulses for every angle of rotation, so that, and the pulse received by the servo motor forms an echo, or closed loop, in this way, the The system will know how many pulses are sent to the servo motor and how many pulses are received back at the same time, so that it can control the rotation of the motor very precisely and thus achieve precise positioning, which can reach 0.001mm.

DC servo motors are divided into brushed and brushless motors. Brush motor is low cost, simple structure, large starting torque, wide speed range, easy to control, requires maintenance, but maintenance is not convenient (changing carbon brushes), generates electromagnetic interference, and has environmental requirements. Therefore it can be used in cost-sensitive general industrial and civil applications.

Post time: Nov-25-2022