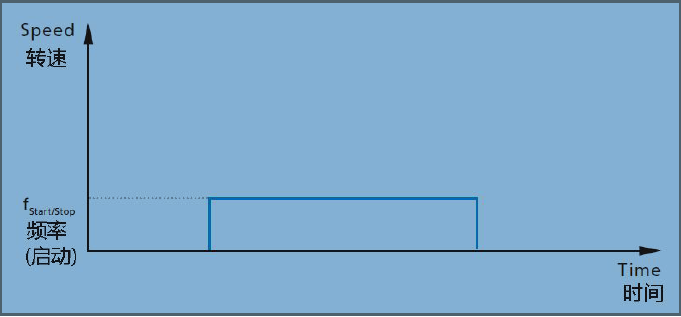

①Depending on the type of motion profile, the analysis is different.Start-Stop operation: In this operation mode, the motor is hooked up to the load and and operates at constant speed.The motor has to accelerate the load (overcome inertiaand friction) within the first step to the commanded frequency.

Failure mode: Stepper motor does not start

|

Reasons |

Solutions |

|

Load is too high |

Wrong motor, select a bigger motor |

|

Frequency too high |

Reduce requency |

|

If the motor oscillates from left to right, one phase may be broken or not connected |

Replace or repair motor |

|

Phase current is not appropriate |

Increase phase current , at least during the first few steps. |

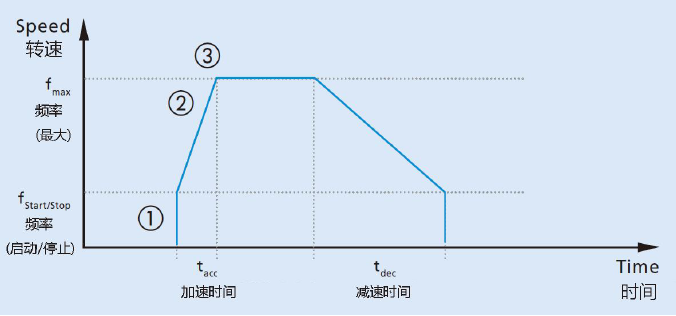

②Acceleration mode: In this case, the Stepper motor is allowed to accelerate to the maximum frequency with an acceleration rate preset in the driver.

Failure mode: Stepper motor does not start

For reasons and solutions see ① section "Start-Stop operation".

Failure mode: Stepper motor does not finish the acceleration ramp.

| Reasons | Solutions |

| Motor trapped in resonance frequency | ● Increase the acceleration to go through the resonancefrequency quickly●Select start-stop frequency above resonance point●Use half-stepping or micro-stepping●Add a mechanical damper which can take the form of aninertial disk on rear shaft |

| Wrong supply voltage or current setting (too low) | ● Increase voltage or current (it is allowed to set a higher valuefor a short period)●Test lower impedance motor●Use constant current drive (if constant voltage drive is used) |

| Top speed too high | ●Reduce top speed●Reduce the acceleration ramp |

| Bad quality of the acceleration ramp from theelectronics (happens with digital ramps) | ●Try with another driver |

Failure mode: Stepper motor finishes acceleration but stalls when constant speed is reached.

|

Reasons |

Solutions |

|

The Stepper motor is operating at the limit of its ability and stalls due to too high acceleration. The equilibrium position is overshooted, causing rotor vibrations and instability. |

● Select a smaller acceleration rate or use two differentacceleration levels, high at start, lower towards top speed●Increase torque● Add a mechanical damper on the rear shaft. Note thatthis will add rotor's inertia and may not solve the problemif the top speed is at the limit of the motor.

●Drive the motor using micro-stepping |

③Increase of the pay load over time

In some cases, the motor runs normally for a long period of time but lose steps after some time. In that case, it is likely that the load seen by the motor has changed. It can come from the wear of the motor bearings or from an external event.

Solutions:

● Verify the presence of an external event: Has the mechanism driven by the motor changed?

● Verify the bearing wear: Use ball bearings instead of sintered sleeve bearing for extended motor life time.

● Verify if the ambient temperature has changed. Its influence on the bearing lubricant viscosity is not insignificant for micro motors. Use lubricants suitable for the operating range. (Example: lubricant may become viscous at extreme temperatures, or after prolonged use, which will increase pay load)

Post time: Nov-16-2022