Surveillance cameras play a vital role in modern security monitoring, and with the advancement of technology, the performance and functional requirements for cameras are getting higher and higher. Among them, 8 mm miniature slider stepping motor, as an advanced drive technology, has been widely used in surveillance cameras. In this paper, we will discuss the application and working principle of 8mm micro-slider stepper motor in surveillance camera.

一,8 mm micro-slider stepper motor introduction

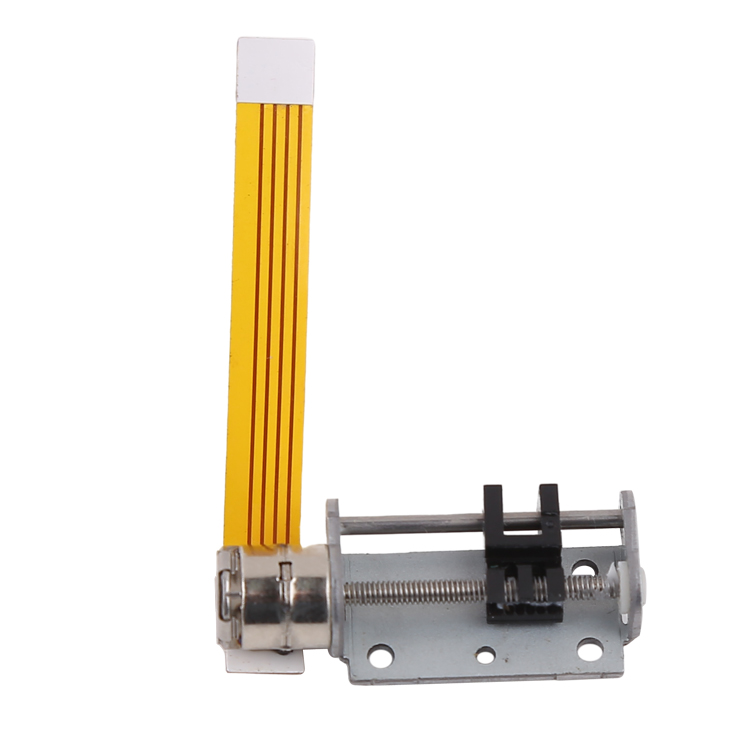

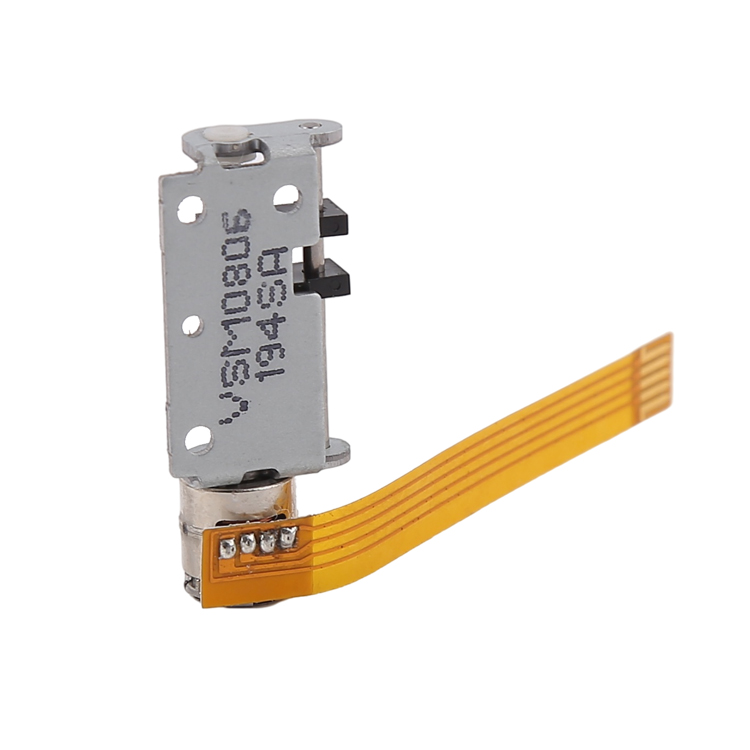

8 mm miniature slider stepper motor is a small size, high precision, low power consumption of the motor, the core part of which consists of the rotor, stator and slider. The stepper motor converts electrical energy into mechanical energy of angular or linear displacement by receiving pulse signals, so as to achieve precise positioning and motion control. The slider is connected to the output shaft of the stepper motor to achieve precise displacement within the linear motion range of the motor.

二,the application in the surveillance camera

Auto-tracking: In surveillance cameras, the auto-tracking function uses the stepper motor to precisely control the camera angle and position so that the camera can automatically track the target. When the target enters the field of view of the camera, the control system identifies the target through the target detection algorithm and calculates the target's movement trajectory. Then, the stepper motor receives the control signal and drives the camera to rotate and shift accordingly to achieve automatic tracking of the target.

Auto Focus: The stepper motor plays a key role in the auto focus process. When the camera captures the target, the control system sends out the focusing command, and the stepping motor drives the lens assembly to move, so that the distance between the lens and the target reaches an optimal state, thus realising a clear and sharp image effect.

Auto Zoom: The auto zoom function is realised by the stepper motor driving the lens to telescope. By controlling the rotation angle or linear displacement of the stepper motor, the focal length of the lens can be precisely adjusted to achieve a continuous zoom effect in the surveillance camera. This enables the surveillance system to obtain clear and stable images at different distances.

Auto Scan: The stepper motor drives the camera to move horizontally and vertically during the auto scanning process, enabling the camera to cover a wider surveillance area. Through the pulse signal sent by the control system, the stepping motor can precisely control the moving speed and direction of the camera, so as to realise all-round and dead-angle-free monitoring coverage.

三,Working Principle

The working principle of 8mm miniature slider stepper motor is based on the interaction of magnetic field and current. There are multiple magnetic poles of different polarity inside the stator and multiple tooth poles made of magnetically conductive material on the rotor. When a current passes through a certain pair of magnetic poles of the stator, a magnetic attraction is generated, which attracts the rotor to rotate to a specific position. By energising the magnetic poles of the stator in a certain order, the continuous rotation of the rotor can be controlled. The rotation of the rotor drives the output shaft connected to the slider to rotate or move linearly, thus achieving precise control of the stepper motor.

四,Advantages and Challenges

Advantages: 8 mm miniature slider stepper motor has the advantages of small size, high precision, low power consumption, etc., which is very suitable for applications where space is limited and high precision control is required, such as surveillance cameras. In addition, stepper motors also have the advantages of fast response speed, high reliability and long life, which can meet the needs of long-time continuous work.

Challenges: Despite their many advantages, 8 mm miniature slider stepper motors face a number of challenges in practical applications. For example, due to its small size, it requires high assembly accuracy and mechanical stability; at the same time, due to its dependence on pulse signals for control, it also requires high synchronisation and stability of the control system. In addition, for different application scenarios and demands, it is necessary to select the appropriate stepper motor models and specifications, and carry out targeted optimisation and adjustment.

In summary, the 8 mm miniature slider stepper motor, as an advanced drive technology, has a wide range of application prospects in surveillance cameras. It not only improves the automation level and intelligence of the monitoring system, but also meets the demand for high-quality, all-round monitoring. However, in order to give full play to its advantages and meet the challenges, in-depth research and continuous optimisation of the motor design, control system and assembly process are still required. In the future, with the advancement of technology and the growth of application demand, the application of 8 mm miniature slider stepping motors in surveillance cameras will be more extensive and in-depth.

Post time: Jan-25-2024