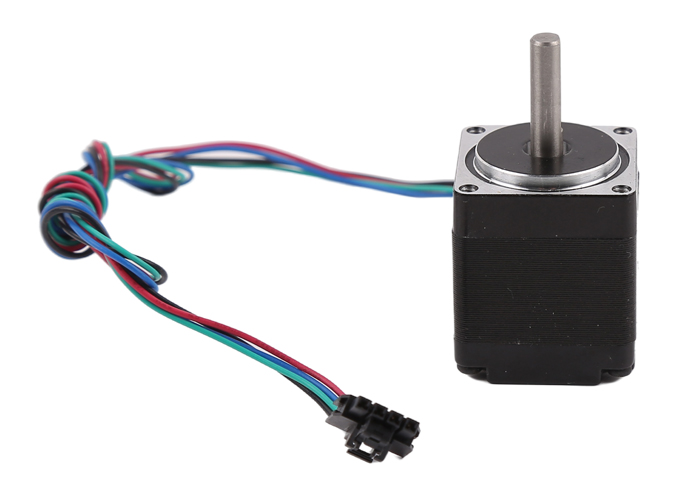

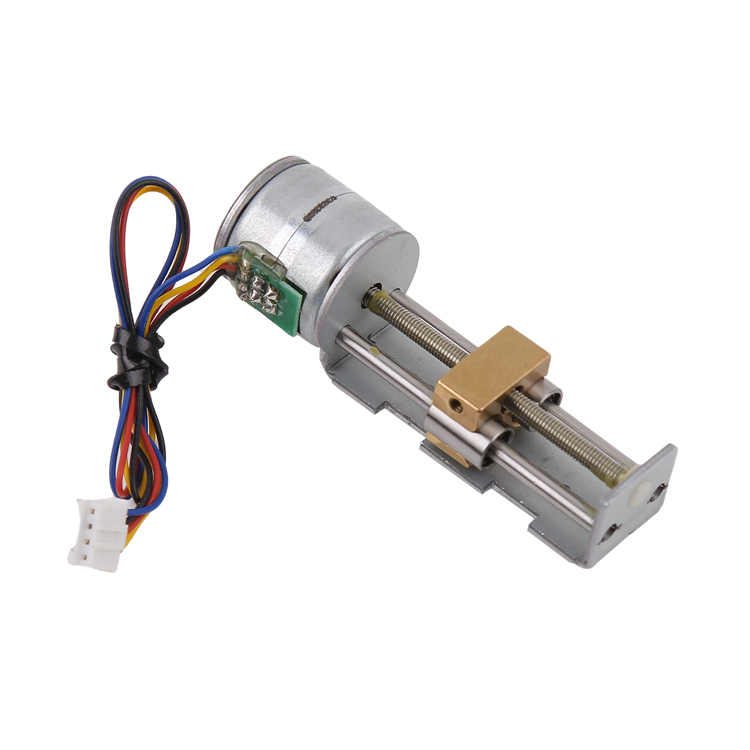

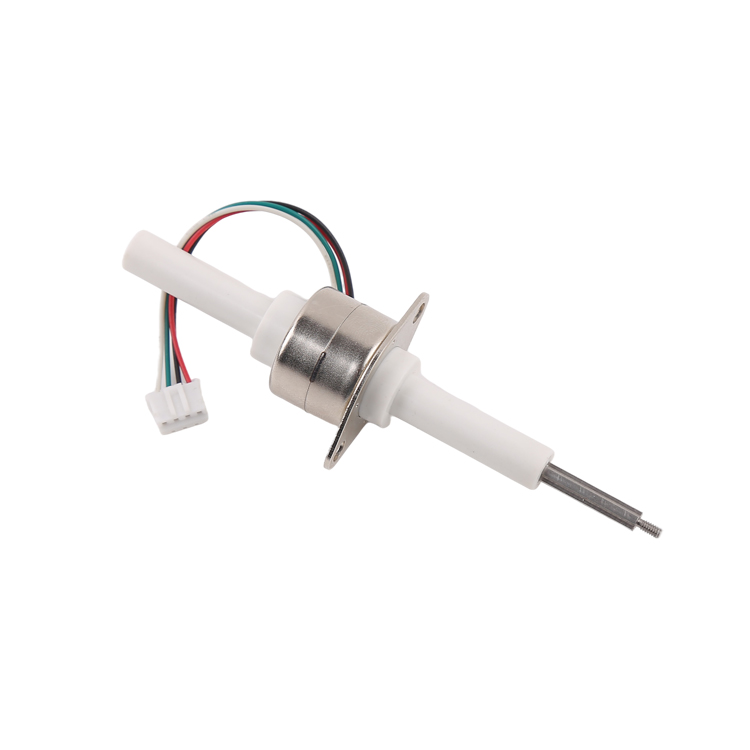

Stepper motors are open-loop control elements that convert electrical pulse signals into angular or linear displacements, and are widely used in a variety of automation equipment and systems. However, in the course of use, stepper motors also encounter some common problems that require proper maintenance.

一. Common problems with stepper motors

1. Stepping motor operation is not normal

Stepping motor operation is not normal may be due to improper driver parameter settings, motor and driver connection is poor, the motor itself is faulty and other reasons. In order to solve this problem, you need to check whether the driver parameters are set correctly, whether the motor is well connected to the driver, and whether the motor is faulty.

2. Stepping motor out of step

Stepping motor out of step refers to the motor in the operation process, the actual position and the command position is not consistent. Lost step may be caused by excessive motor load, insufficient driver current, improper setting of the driver fine score. The solution to this problem is to reduce the motor load, increase the driver current, adjust the driver fine points.

3. Stepping motor noise

Excessive stepper motor noise may be caused by worn motor bearings, bad gears, poor connection between the motor and the driver, and so on. In order to reduce the noise, you need to check the status of the motor bearings and gears to ensure that they are in good working condition, and check whether the connection between the motor and the driver is good.

4. Stepping motor heating

Stepping motor heating may be caused by excessive motor load, excessive driver current, and poor motor heat dissipation. In order to avoid overheating of the motor, it is necessary to reduce the motor load, adjust the driver current, and strengthen the motor heat dissipation.

二, stepper motor maintenance methods

1. Regularly check the motor and driver

In order to ensure the normal operation of the stepper motor, you need to regularly check the status of the motor and driver. The inspection includes the wear and tear of the motor bearings and gears, whether the connection between the motor and the driver is good, and whether the driver parameters are set correctly. Problems found in a timely manner in order to avoid the occurrence of failures.

2. Regularly clean the motor and drive

Stepper motors and drives accumulate dust and dirt during use, which may affect their performance. Therefore, it is necessary to clean the motor and driver regularly to keep them clean and tidy. When cleaning, use a dry cloth to wipe the surface of the motor casing and driver, and avoid using chemical cleaners or water.

3. Pay attention to the environment in which the motor is used

The environment in which the stepper motor is used will also affect its performance and service life. Therefore, in the use of stepper motors, attention should be paid to avoid using the motor in humid, high temperature, high humidity and other harsh environments. In addition, the motor should be avoided from mechanical shock and vibration to ensure the stability and reliability of the motor.

4. Maintenance of the motor when it is out of use for a long period of time

If the stepper motor is not used for a long period of time, proper maintenance is also required to avoid motor damage. Maintenance methods include running the motor with power on regularly to maintain the activity and stability of the motor; at the same time, it is also necessary to check whether the connecting wires and plugs of the motor are loose or damaged in order to avoid damage to the motor due to poor contact.

In conclusion, stepper motors encounter some common problems during use and require proper maintenance. Through regular inspection, cleaning, paying attention to the use of the environment and maintenance when out of service for a long period of time, you can extend the service life of the stepper motor and improve the stability and reliability of the equipment.

Post time: Mar-23-2024