An electric motor is a device that converts electrical energy into mechanical energy, and since Faraday's invention of the first electric motor, we've been able to live our lives without this device everywhere.

Nowadays, cars are rapidly changing from being predominantly mechanical to electrically-driven devices, and the use of motors in cars is becoming more and more widespread. Many people may not be able to guess how many motors are fitted in their car, and the following introduction will help you to discover the motors in your car.

Applications of motors in cars

To find out where the motor is in your car, the power seat is the ideal place to find it. In economy cars, motors typically provide fore and aft adjustment and backrest tilt. In premium cars, electric motors can control height adjustment, for example, seat bottom cushion recline, lumbar support, headrest adjustment and cushion firmness, among other features that can be used without electric motors. Other seat features that use electric motors include power seat folding and power loading of the rear seats.

Windscreen wipers are the most common example of electric motor applications in modern cars. Typically, every car has at least one wiper motor for the front wipers. Rear window wipers are becoming increasingly popular with SUVs and cars with barn-door backs, which means that rear wipers and corresponding motors are present in most cars. Another motor pumps washer fluid to the windscreen, and in some cars to the headlights, which may have their own little wiper.

Almost every car has a blower that circulates air through the heating and cooling system; many vehicles have two or more fans in the cabin. Higher-end vehicles also have fans in the seats for cushion ventilation and heat distribution.

In the past, windows were often opened and closed manually, but now power windows are common. Hidden motors are housed in each window, including sunroofs and rear windows. The actuators used for these windows can be as simple as relays, but safety requirements (such as detecting obstacles or clamping objects) lead to the use of smarter actuators with motion monitoring and drive force limitation.

Changing from manual to electric, car locks are becoming more convenient. The benefits of motorised control include convenient features such as remote operation, and enhanced safety and intelligence such as automatic unlocking after a collision. Unlike power windows, power door locks must retain the option of manual operation, so this affects the design of the motor and structure of the power door lock.

Indicators on dashboards or clusters may have evolved into light-emitting diodes (LEDs) or other types of displays, but now every dial and gauge uses small electric motors. Other motors in the convenience-providing category include common features such as side mirror folding and position adjustment, as well as more moody applications such as convertible tops, retractable pedals, and glass dividers between driver and passenger.

Under the bonnet, electric motors are becoming more common in a number of other places. In many cases, electric motors are replacing belt-driven mechanical components. Examples include radiator fans, fuel pumps, water pumps and compressors. There are several advantages to changing these functions from belt drive to electric drive. One is that the use of drive motors in modern electronic equipment is more energy efficient than using belts and pulleys, resulting in benefits such as improved fuel efficiency, reduced weight and lower emissions. Another advantage is that the use of electric motors rather than belts allows more freedom in mechanical design, as the mounting locations of pumps and fans do not have to be constrained by the serpentine belt that must be attached to each pulley.

Trends in in-vehicle motor technology

Electric motors are indispensable in the places marked in the diagram above, and, subsequently, as the car becomes more electronic and the progress of autonomous driving and intelligence is made, electric motors will be used more and more in the car, and the type of motors for the drive is also changing.

Whereas previously most motors in cars used standard 12V automotive systems, dual voltage 12V and 48V systems are now becoming mainstream, with the dual voltage system allowing some of the higher current loads to be removed from the 12V battery. The advantage of using a 48V supply is a fourfold reduction in current for the same power, and the accompanying reduction in weight of cables and motor windings. Applications with high-current loads that may be updated to 48V power include starter motors, turbochargers, fuel pumps, water pumps and cooling fans. Placing a 48V electrical system for these components may save approximately 10 per cent in fuel consumption.

Understanding Motor Types

Different applications require different motors, and motors can be categorised in a variety of ways.

1. Classification based on operating power source - Depending on the operating power source of the motor, it can be classified into DC motors and AC motors. Among them, AC motors are also divided into single-phase motors and three-phase motors.

2. According to the working principle - according to the different structure and working principle, the motor can be divided into DC motor, asynchronous motor and synchronous motor. Synchronous motors can also be divided into permanent magnet synchronous motors, reluctance synchronous motors and hysteresis motors. Asynchronous motor can be divided into induction motor and AC commutator motor.

3. Classification according to the starting and running mode - motor according to the starting and running mode can be divided into capacitor-started single-phase asynchronous motor, capacitor-run single-phase asynchronous motor, capacitor-started running single-phase asynchronous motor and split-phase single-phase asynchronous motor.

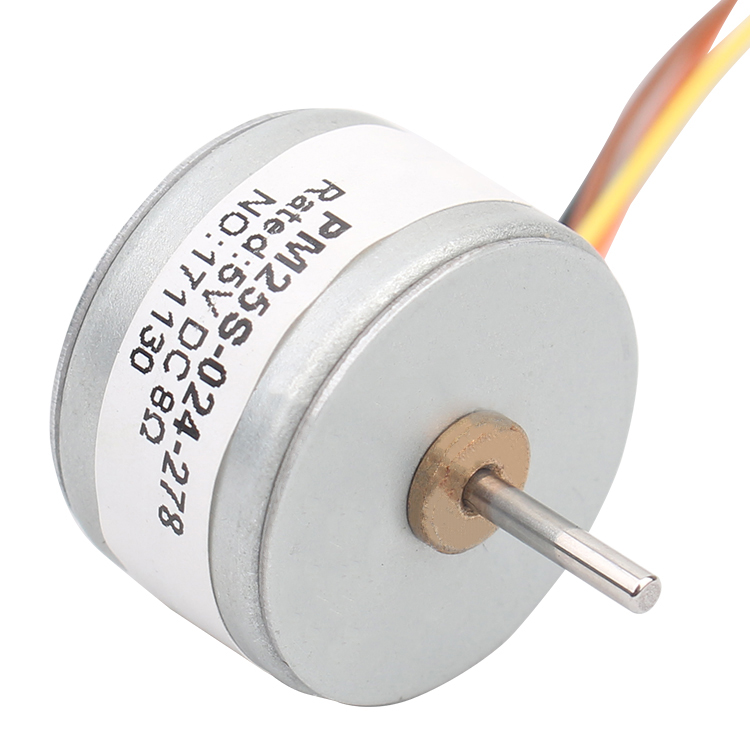

4. Classification according to the use - electric motors can be divided into drive motors and control motors according to the use. Drive motor is divided into power tools (including drilling, polishing, grinding, slotting, cutting, reaming and other tools) with electric motors, home appliances (including washing machines, electric fans, refrigerators, air conditioners, tape recorders, VCRs, video recorders, DVD players, hoovers, cameras, hairdryers, electric shavers, etc.) with electric motors and other general-purpose small machinery and equipment (including a variety of small machine tools, small machinery, medical equipment, electronic instruments, etc.). Control motors are divided into stepper motors and servo motors.

5. Classification according to the structure of the rotor - motor according to the structure of the rotor can be divided into cage induction motor (the old standard is called squirrel cage asynchronous motor) and wire-wound rotor induction motor (the old standard is called wire-wound asynchronous motor).

6. Classification according to the operating speed - motor according to the operating speed can be divided into high-speed motors, low-speed motors, constant-speed motors, speed motors.

Currently, most motors in automotive body applications use brushed DC motors, which is a traditional solution. These motors are simple to drive and relatively inexpensive due to the commutation function provided by the brushes. In some applications, brushless DC (BLDC) motors offer significant advantages in terms of power density, which reduces weight and provides better fuel economy and lower emissions, and manufacturers are choosing to use BLDC motors in windscreen wipers, cabin heating, ventilation and air conditioning (HVAC) blowers and pumps. In these applications, motors tend to run for long periods of time rather than transient operation like power windows or power seats, where the simplicity and cost-effectiveness of brushed motors continue to be advantageous.

Electric motors suitable for electric vehicles

The shift from fuel-efficient vehicles to purely electric vehicles will see a shift to motor-driven engines at the heart of the car.

The motor drive system is the heart of an electric vehicle, which consists of a motor, a power converter, various detection sensors and a power supply. Suitable motors for electric vehicles include: DC motors, brushless DC motors, asynchronous motors, permanent magnet synchronous motors, and switched reluctance motors.

DC motor is a motor that converts DC electrical energy into mechanical energy, and is widely used in electric power drag because of its good speed regulation performance. It also has the characteristics of large starting torque and relatively simple control, therefore, any machinery that starts under heavy load or requires uniform speed regulation, such as large reversible rolling mills, winches, electric locomotives, trams and so on, is suitable for the use of DC motors.

Brushless DC motor is very much in line with the load characteristics of electric vehicles, with low-speed large torque characteristics, can provide a large starting torque to meet the acceleration requirements of electric vehicles, at the same time, it can run in low, medium and high wide speed range, it also has a high efficiency characteristics, in the light-loaded conditions, has a high efficiency. The disadvantage is that the motor itself is more complex than an AC motor and the controller is more complex than a brushed DC motor.

Asynchronous motor, i.e. induction motor, is a device in which the rotor is placed in a rotating magnetic field, and under the action of the rotating magnetic field, a rotating torque is obtained, and thus the rotor rotates. Asynchronous motor structure is simple, easy to manufacture and maintain, it has close to constant speed load characteristics, can meet the requirements of most industrial and agricultural production machinery drag. However, the speed of the asynchronous motor and its rotating magnetic field synchronous speed has a fixed rate of rotation, and thus the speed regulation is poor, not as economic as the DC motor, flexible. In addition, in high-power, low-speed applications, asynchronous motors are not as reasonable as synchronous motors.

Permanent magnet synchronous motor is a synchronous motor that generates a synchronous rotating magnetic field by the excitation of permanent magnets, which act as a rotor to generate a rotating magnetic field, and the three-phase stator windings react through the armature under the action of the rotating magnetic field, inducing three-phase symmetrical currents. The permanent magnet motor is small in size, light in weight, with small rotating inertia and high power density, which is suitable for electric vehicles with limited space. In addition, it has a large torque-to-inertia ratio, strong overload capacity, and a large output torque especially at low rotational speeds, which is suitable for the start-up acceleration of the computerised vehicle. Therefore, permanent magnet motors have been generally recognised by the domestic and foreign electric vehicle sessions and have been used in a number of electric vehicles. For example, most electric vehicles in Japan are driven by permanent magnet motors, which are used in the Toyota Prius hybrid.

Post time: Jan-31-2024