Nema 11 (28mm) hybrid ball screw stepper motor 1.8° Step Angle Voltage 2.1 / 3.7V Current 1A,4 Lead Wires

Nema 11 (28mm) hybrid ball screw stepper motor 1.8° Step Angle Voltage 2.1 / 3.7V Current 1A,4 Lead Wires

Nema 11 (28mm) hybrid stepper motor, bipolar, 4-lead, ball screw, low noise, long life, high performance, CE and RoHS certified.

Description

| Product Name | 28mm hybrid ball screw stepper motor |

| Model | VSM28BSHSM |

| Type | hybrid stepper motors |

| Step Angle | 1.8° |

| Voltage (V) | 2.1 / 3.7 |

| Current (A) | 1 |

| Resistance (Ohms) | 2.1 / 3.7 |

| Inductance (mH) | 1.5 / 2.3 |

| Lead Wires | 4 |

| Motor Length (mm) | 34 / 45 |

| Ambient Temperature | -20℃ ~ +50℃ |

| Temperature Rise | 80K Max. |

| Dielectric Strength | 1mA Max. @ 500V, 1KHz, 1Sec. |

| Insulation Resistance | 100MΩ Min. @500Vdc |

Certifications

Electrical Parameters:

| Motor Size |

Voltage /Phase (V) |

Current /Phase (A) |

Resistance /Phase (Ω) |

Inductance /Phase (mH) |

Number of Lead Wires |

Rotor Inertia (g.cm2) |

Motor Weight (g) |

Motor Length L (mm) |

| 28 | 2.1 | 1 | 2.1 | 1.5 | 4 | 9 | 120 | 34 |

| 28 | 3.7 | 1 | 3.7 | 2.3 | 4 | 13 | 180 | 45 |

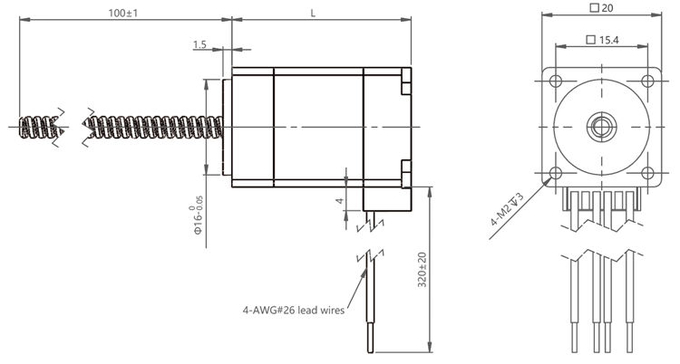

VSM20BSHSM standard external motor outline drawing

Notes:

Lead screw length can be customized

Customized machining is viable at the end of lead screw

Please contact us for more ball screw specifications.

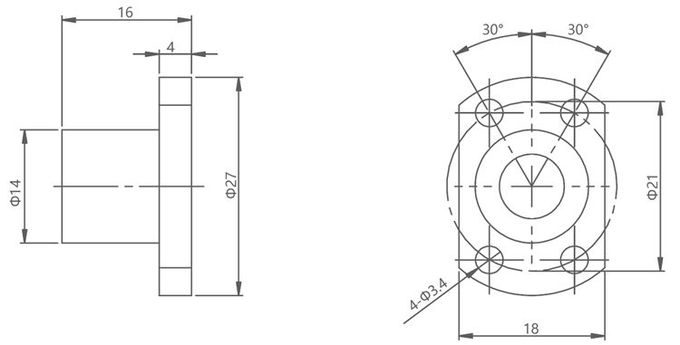

VSM20BSHSMBall nut 0601 outline drawing:

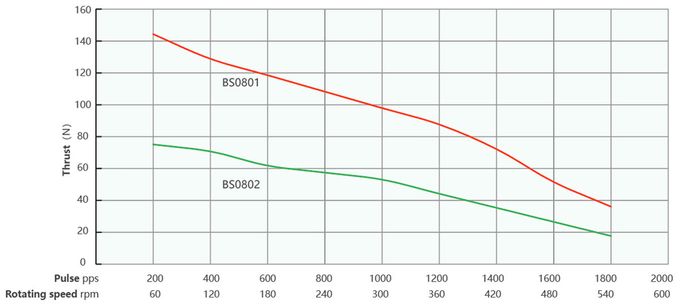

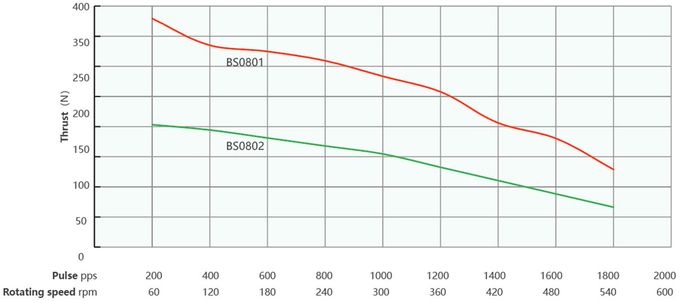

Speed and thrust curve

28 series 34mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

28 series 45mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

|

Lead (mm) |

Linear velocity (mm/s) |

|||||||||

|

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

2 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

Test condition:Chopper drive, no ramping, half micro-stepping, drive voltage 24V

Areas of application:

Automation equipment: These stepper motors can be used in a variety of automation equipment, such as automated production lines, packaging machinery, and automated storage systems. They enable high-precision positioning and motion control, ensuring accurate operation and high efficiency of the equipment.

Robotics: The compact dimensions and high-precision positioning of the 28 mm hybrid ball screw stepper motors make them a commonly used drive in robotics. They can be used to drive, precisely position and coordinate the movement of robot joints for a variety of robotic applications, including industrial robots, service robots, medical robots and more.

Electronics: These stepper motors are used in various types of electronic devices, such as optical equipment, precision instruments, 3D printers, and more. They provide high-precision and reliable motion control for electronic equipment applications that require precise positioning and fine motion.

Medical Devices: 28mm hybrid ball screw stepper motors are used in a wide range of medical devices, such as surgical robots, medical scanning equipment, drug delivery systems, and more. They provide precise position control and stable motion to meet the high precision and reliability requirements of medical devices.

Automotive: These stepper motors are used in various applications in the automotive industry, such as automotive seat adjustment, sunroof control, automotive door locking mechanisms, etc. They provide precise position control and stable motion. They provide precise position control and reliable power output, and are suitable for the automotive industry's requirements for high precision and reliability.

Aerospace: 28 mm hybrid ball screw stepper motors are also used in aerospace applications. They can be used for positioning and motion control in aerospace equipment, such as satellite orientation systems, internal mechanisms in aircraft, etc.

Advantage

Compact Size: The 28mm form factor of these motors allows for a compact and space-saving design. They are suitable for applications where size constraints are a consideration.

Improved Positioning Accuracy: The combination of hybrid stepper motor technology and the precision of the ball screw mechanism enables enhanced positioning accuracy. This is particularly beneficial for applications that require precise and repeatable motion control.

Smooth and Quiet Operation: Hybrid ball screw stepper motors offer smooth and quiet operation due to the ball screw's low friction characteristics. This makes them suitable for applications where noise reduction is desired or where smooth motion is essential, such as in scientific instruments or camera positioning systems.

High Torque-to-Size Ratio: Despite their compact size, 28mm hybrid ball screw stepper motors can deliver significant torque. This high torque-to-size ratio makes them suitable for applications that require both compactness and sufficient torque to drive the load effectively.

Energy Efficiency: The ball screw mechanism in these motors provides efficient power transmission, resulting in reduced energy consumption. This makes them energy-efficient and helps minimize heat generation during operation.

Backlash Reduction: The ball screw mechanism minimizes or eliminates backlash, which is the play or clearance between the screw and nut. This results in improved accuracy and repeatability of positioning, making these motors suitable for applications that demand precise motion control.

Long Service Life: The combination of a robust hybrid stepper motor design and the durability of the ball screw mechanism contributes to a long service life. This ensures reliable and consistent performance over an extended period.

Wide Range of Customization: 28mm hybrid ball screw stepper motors are available with various customization options such as different step angles, winding options, and shaft configurations. This allows for flexibility in meeting specific application requirements.

Motor Selection Requirements:

►Movement/mounting direction

►Load Requirements

►Stroke Requirements

►End machining requirements

►Precision Requirements

►Encoder Feedback Requirements

►Manual Adjustment Requirements

►Environmental Requirements

Production workshop