Nema 23 (57mm) hybrid ball screw stepper motor 1.8° Step Angle 4 Lead Wires for Medical diagnostic equipment

Nema 23 (57mm) hybrid ball screw stepper motor 1.8° Step Angle 4 Lead Wires for Medical diagnostic equipment

Nema 23 (57mm) hybrid stepper motor, bipolar, 4-lead, ball screw, low noise, long life, high performance, CE and RoHS certified.

Large load capacity, small vibration, low noise, fast speed, fast response, smooth operation, long life, high positioning accuracy (up to ±0.005mm)

Description

| Product Name | 57mm hybrid ball screw stepper motor |

| Model | VSM57BSHSM |

| Type | hybrid stepper motors |

| Step Angle | 1.8° |

| Voltage (V) | 2.3 / 3 / 3.1 / 3.8 |

| Current (A) | 3 / 4 |

| Resistance (Ohms) | 0.75 / 1 / 0.78 / 0.95 |

| Inductance (mH) | 2.5 / 4.5 / 3.3 / 4.5 |

| Lead Wires | 4 |

| Motor Length (mm) | 45 / 55 / 65 / 75 |

| Ambient Temperature | -20℃ ~ +50℃ |

| Temperature Rise | 80K Max. |

| Dielectric Strength | 1mA Max. @ 500V, 1KHz, 1Sec. |

| Insulation Resistance | 100MΩ Min. @500Vdc |

Certifications

Electrical Parameters:

|

Motor Size |

Voltage /Phase (V) |

Current /Phase (A) |

Resistance /Phase (Ω) |

Inductance /Phase (mH) |

Number of Lead Wires |

Rotor Inertia (g.cm2) |

Motor Weight (g) |

Motor Length L (mm) |

|

57 |

2.3 |

3 |

0.75 |

2.5 |

4 |

150 |

580 |

45 |

|

57 |

3 |

3 |

1 |

4.5 |

4 |

300 |

710 |

55 |

|

57 |

3.1 |

4 |

0.78 |

3.3 |

4 |

400 |

880 |

65 |

|

57 |

3.8 |

4 |

0.95 |

4.5 |

4 |

480 |

950 |

75 |

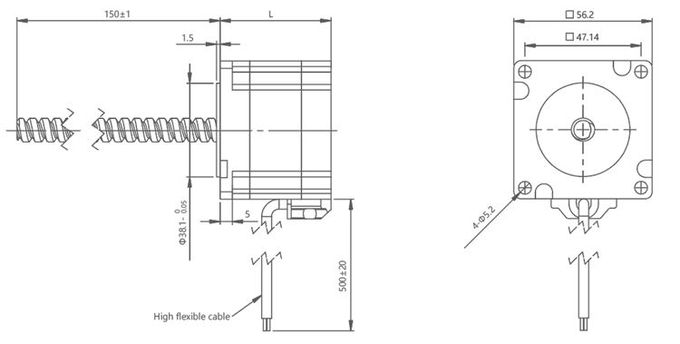

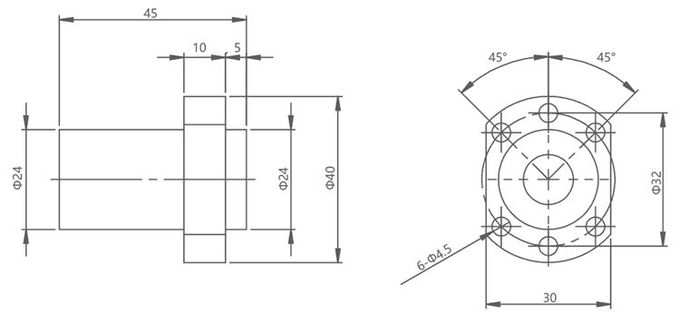

VSM57BSHSM standard external motor outline drawing:

Notes:

Lead screw length can be customized

Customized machining is viable at the end of lead screw

Please contact us for more ball screw specifications.

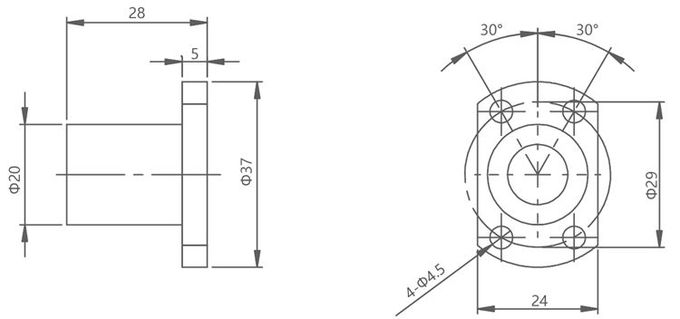

VSM57BSHSMBall nut 1202 outline drawing:

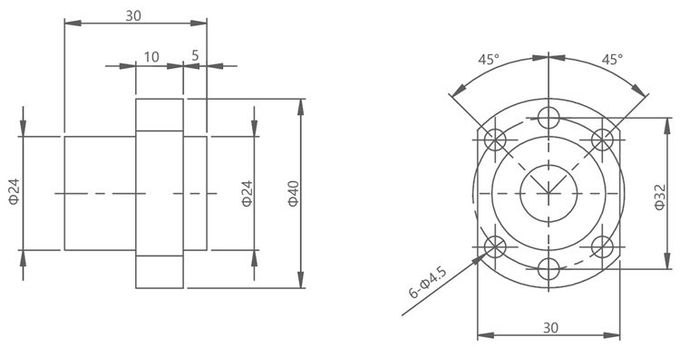

VSM57BSHSMBall nut 1205 outline drawing:

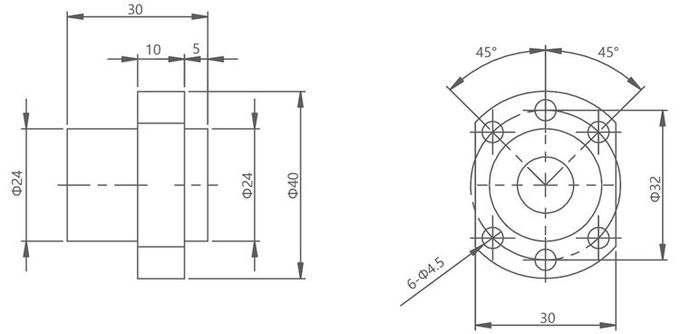

VSM57BSHSMBall nut 1210 outline drawing:

VSM57BSHSMBall nut 1210 outline drawing:

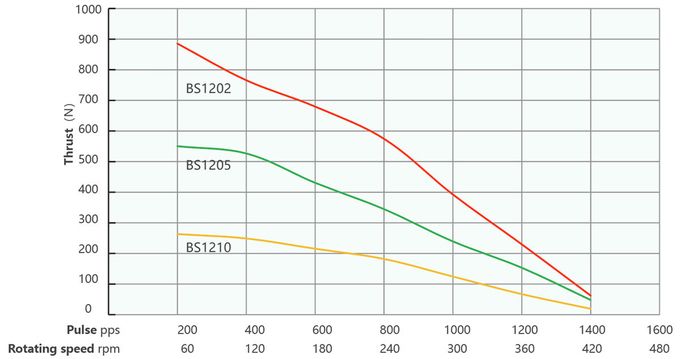

Speed and thrust curve

57 series 45mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

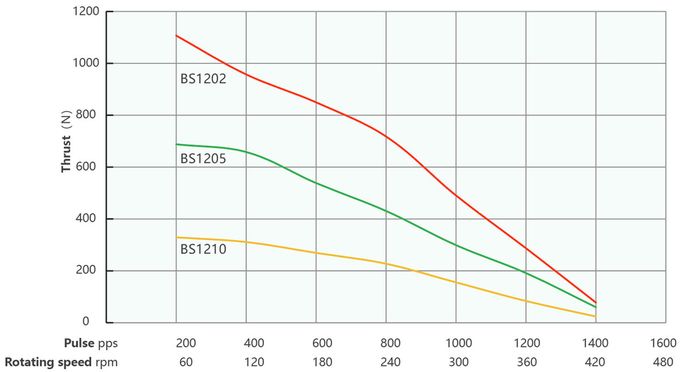

57 series 55mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

|

Lead (mm) |

Linear velocity (mm/s) |

|||||||

|

2 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

|

5 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

|

10 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

Test condition:Chopper drive, no ramping, half micro-stepping, drive voltage 40V

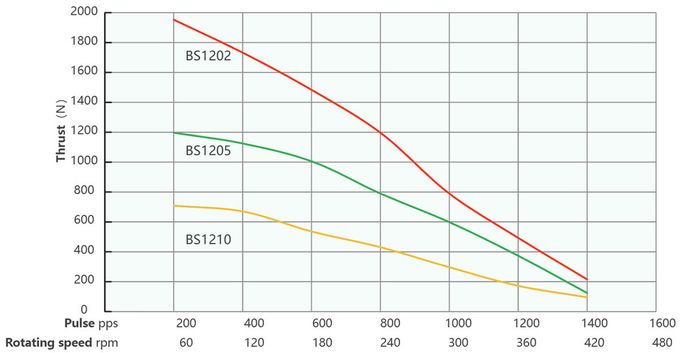

57 series 65mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

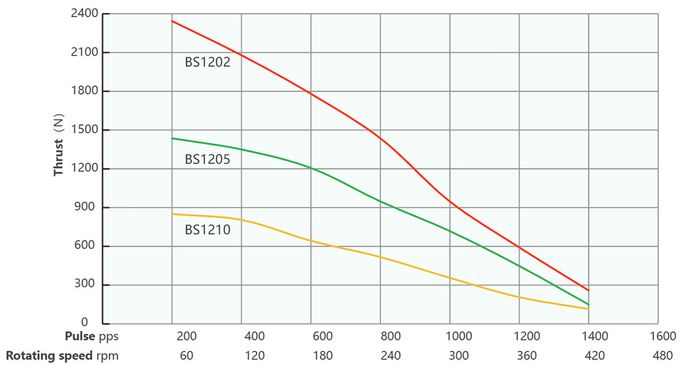

57 series 75mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

|

Lead (mm) |

Linear velocity (mm/s) |

|||||||

|

2 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

|

5 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

|

10 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

Test condition:Chopper drive, no ramping, half micro-stepping, drive voltage 40V

Areas of application:

Medical diagnostic equipment: 57mm hybrid ball screw stepper motors can be used in medical diagnostic equipment such as image scanners, CT scanners, X-ray equipment, MRI instruments and so on. Their high precision position control and stability enable precise movement and positioning during medical image acquisition and processing.

Life Science Instruments: In life science research and experimentation, 57mm hybrid ball screw stepper motors are used in automated liquid handling systems, high-throughput screening equipment, cell culture devices, gene sequencers, and more. The high precision and reliability of these motors enable them to meet the demand for precise motion and position control in experimental equipment.

Robotics: 57mm hybrid ball screw stepper motors are widely used in robotics for joint drives, robotic arm motion, and precision positioning. These motors are characterized by high torque, high resolution and low noise to meet the demand for precision motion and control in robotics applications.

Laser equipment: 57mm hybrid ball screw stepper motors can be used in laser equipment for tasks such as focus adjustment, panning table, and optical path control. Its high-precision position control and stability enable it to realize precise focusing and positioning of the laser beam.

Analytical Instruments: In various types of laboratory analytical instruments, 57mm hybrid ball screw stepper motors can be used in automated sample processing, sample feeding systems, liquid chromatographs, gas chromatographs, etc.. The high-precision motion and stable performance of these motors play an important role in improving the accuracy and efficiency of laboratory analysis.

Semiconductor and electronic production equipment: 57mm hybrid ball screw stepper motors are used for precision positioning and automation control in semiconductor and electronic production equipment. For example, they can be used in semiconductor chip test equipment, packaging machines, surface mount technology, printed circuit board manufacturing and other areas to provide high-speed, high-precision and reliable motion control.

Non-standard automation equipment and various types of automation equipment: 57mm hybrid ball screw stepper motors are suitable for a wide range of non-standard automation equipment and automated production lines. They can be used in positioning equipment, automatic assembly systems, packaging equipment, printing machinery, textile equipment, etc. They provide precise position control and reliable motion performance to meet the automation needs in different fields.

Advantage

High Torque-to-Inertia Ratio: Hybrid ball screw stepper motors have a high torque-to-inertia ratio, which means they can deliver significant torque output relative to their size and weight. This makes them ideal for applications that require high torque in a compact form factor, such as robotics, CNC machines, and automation systems.

High Acceleration and Deceleration: These motors are capable of rapid acceleration and deceleration, allowing for quick and precise movements. The low inertia of the rotor and the high torque output enable the motor to respond rapidly to control signals, resulting in faster start-stop times and improved overall system performance.

Smooth Microstepping: Hybrid ball screw stepper motors are well-suited for microstepping operation, which allows for finer resolution and smoother motion control. Microstepping divides each full step into smaller sub-steps, reducing step size and minimizing vibration, noise, and resonance effects. This feature is particularly beneficial in applications that require smooth and precise motion, such as 3D printers and linear positioning systems.

Low Backlash: The ball screw mechanism in these motors helps minimize backlash, which is the play or clearance between the rotor and the load. Low backlash ensures accurate positioning and repeatability, as there is minimal lost motion when changing directions or reversing movement. This is crucial for applications that require precise and repeatable positioning, such as pick-and-place machines and optical systems.

High Dynamic Response: The combination of the hybrid stepper motor and ball screw mechanism allows for high dynamic response, meaning the motor can quickly and accurately follow changes in the control signal. This responsiveness is essential for applications that involve rapid changes in speed, direction, or position, such as high-speed machining and dynamic motion control systems.

Thermal Efficiency: Hybrid ball screw stepper motors are designed to have good thermal efficiency, allowing for effective heat dissipation during operation. This helps prevent overheating and ensures stable motor performance, even during prolonged use or in demanding applications.

Cost-Effective Solution: Hybrid ball screw stepper motors offer a cost-effective solution for applications that require high precision and torque. Compared to more complex and expensive servo motor systems, hybrid stepper motors provide a balance between performance, cost, and ease of use. They are often a preferred choice for applications where cost is a significant factor, without compromising on quality and performance.

Motor Selection Requirements:

►Movement/mounting direction

►Load Requirements

►Stroke Requirements

►End machining requirements

►Precision Requirements

►Encoder Feedback Requirements

►Manual Adjustment Requirements

►Environmental Requirements

Production workshop