Low-noise 50 mm diameter permanent magnet stepper motor with gears

Description

50BYJ46 is a 50 mm diameter permanent magnet motor with gears, low noise permanent magnet stepper motor for saliva analyzer

The motor has a gearbox gear ratio of 33.3:1, 43:1, 60:1 and 99:1, which can be selected by customers according to their requirements.

The motor is suitable for 12V DC drive, low noise, cheap and reliable performance, it has been widely used in various industry fields, and it is continuously produced every year, which makes the quality of this motor very stable and the price is much lower than other motors.

Common PM unipolar stepper motor driver is able to drive this kind of motor.

If you are interested, please feel free to contact us.

Parameters

|

Voltage (V) |

Resistance(Ω) |

Pull-in torque 100PPS(mN*m) |

Detent torque (mN*m) |

Unload pull-in Frequency(PPS) |

Step angle (1-2phase) |

|

12 |

50 |

≥196 |

≥260 |

≥320 |

7.5°/33.3 |

|

12 |

40 |

≥200 |

≥260 |

≥350 |

7.5°/43 |

|

12 |

60 |

≥392 |

≥343 |

≥200 |

7.5°/60 |

|

12 |

70 |

≥550 |

≥600 |

≥200 |

7.5°/99 |

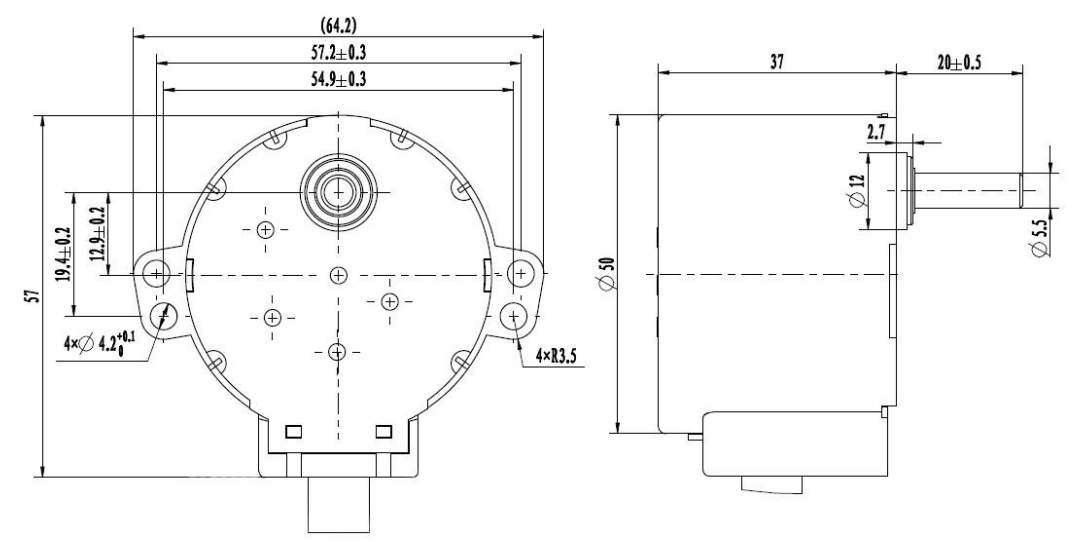

Design drawing:Output shaft customizable

Customizable ltems

Gear ratio,

Voltage:5-24V,

Gear ratio,

Gear material,

Output shaft,

Motor’s cap design customizable

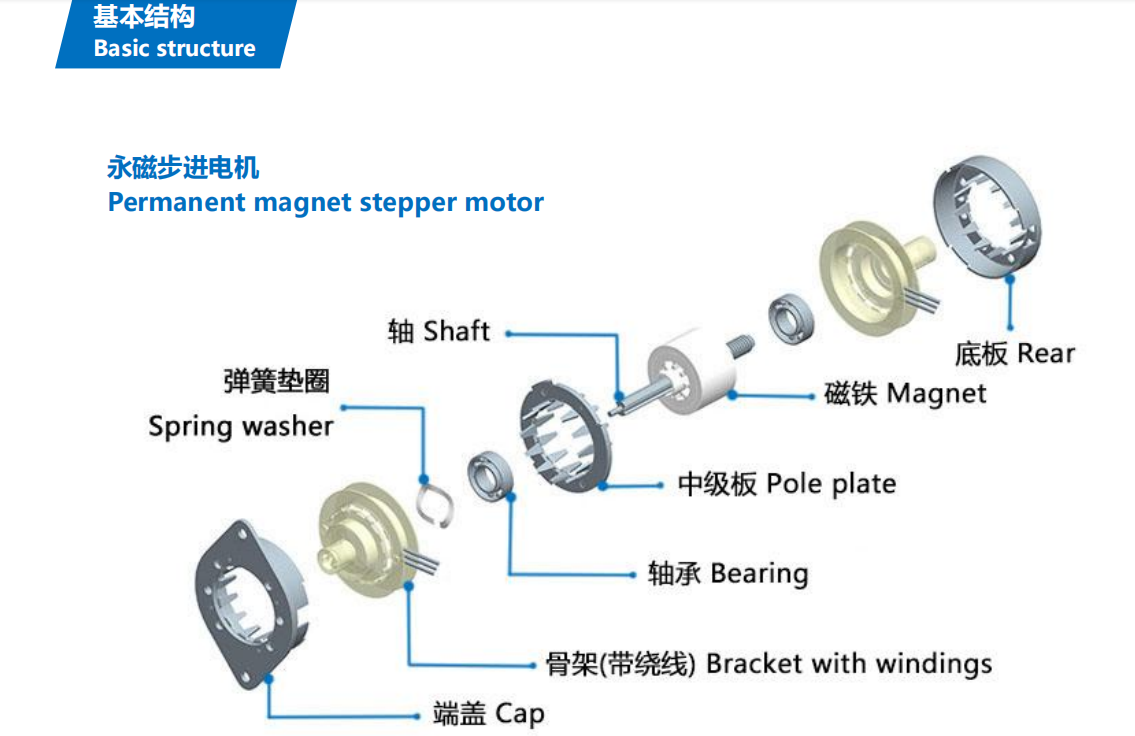

About the basic structure of PM stepper motor

Features & Advantage

1. High precision positioning

Since steppers move in precise repeatable steps, they excel in applications requiring precise

positioning, by the number of steps the motor moves

2. High Precision speed control

Precise increments of movement also allow for excellent control of rotational speed for process

automation and robotics. The rotational speed is determined by the frequency of the pulses.

3. Pause and holding function

With control of the drive, the motor has lock function (there is current through motor windings, but

the motor does not rotate), and there is still a holding torque output.

4. Long life & low electromagnetic interference

The stepper motor has no brushes, and does not need to be commutated by brushes like a brushed

DC motor. There is no friction of the brushes, which increases the service life, has no electric sparks, and reduces electromagnetic interference.

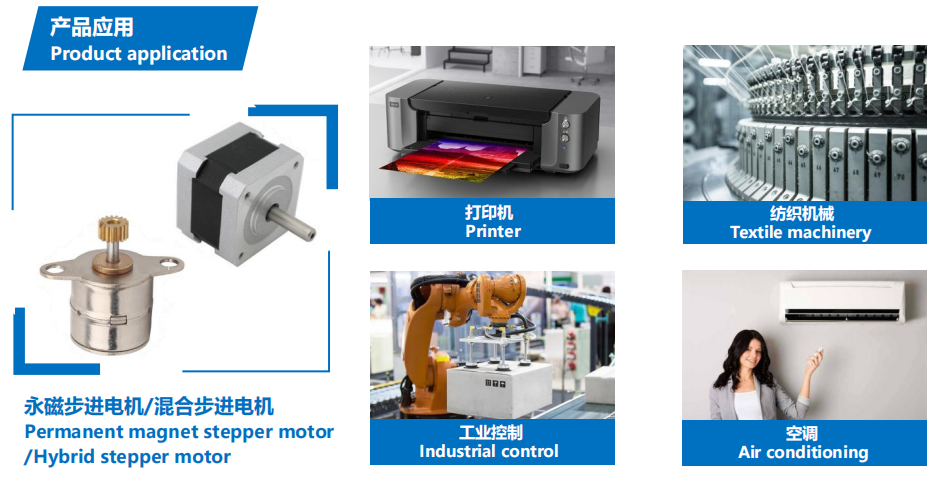

Application of PM stepper motor

Printer,

Textile machinery,

Industrial control,

Saliva Analyzer,

Blood Analyzer,

Welding Machine

Intelligent Security Products

Digital Electronics

sanitary ware,

thermostatic valve,

hot water faucets,

Air conditioning etc.

Working principle of stepper motor

The drive of the stepper motor is controlled by software. When the motor needs to rotate, drive will

apply the stepper motor pulses. These pulses energize stepper motor's in a specified order, thereby

causing the motor's rotor to rotate in a specified direction (clockwise or counter clockwise). So as to

realize proper rotation of the motor. Each time the motor receives a pulse from the driver, it will rotate by a step angle (with full-step drive), and the rotation angle of the motor is determined by the number of driven pulses and step angle.

Lead Time

If we have samples in stock, we can ship out samples in 3 days.

If we do not have samples in stock, we need to produce them, production time is about 20 calendar days.

For mass production, lead time depends on order quantity.

Packaging

Samples are packed in foam sponge with a paper box, shipped by express

Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets

Payment method and payment terms

For samples, in general we accept Paypal or alibaba.

For mass production, we accept T/T payment.

For samples, we collect full payment before production.

For mass production, we can accept 50% pre-payment before production, and collect the rest 50% payment before shipment.

After we cooperate order more than 6 times, we could negotiate other payment terms such as A/S (after sight)

Frequently Asked Question

1.Principle of stepper motor:

The speed of a stepper motor is controlled with a driver, and the signal generator in the controller generates a pulse signal. By controlling the frequency of the pulse signal sent, when the motor receives a pulse signal will move one step (we only consider the whole step drive), you can control the speed of the motor.

2.The reasonable range of stepper motor heat generation:

The extent to which motor heat generation is allowed depends largely on the motor's internal insulation level. The internal insulation will only be destroyed at high temperatures (above 130 degrees). So as long as the internal does not exceed 130 degrees, the motor will not damage the ring, and the surface temperature will be below 90 degrees at that point. Therefore, the surface temperature of stepper motor in 70-80 degrees are normal. Simple temperature measurement method useful point thermometer, you can also roughly determine: with the hand can touch more than 1-2 seconds, not more than 60 degrees; with the hand can only touch, about 70-80 degrees; a few drops of water quickly vaporized, it is more than 90 degrees